Overview

This interactive three day course will focus on the operational part of the cable life cycle and the diagnostic techniques that can be used to gain a better understanding of cable condition.

The course will cover the types of stresses that the whole cable system will experience during its life, the types of ageing phenomena that arise, and how these can be detected. We will also consider the defects that can be introduced during manufacture and installation.

Making reference to international best practice the course will introduce a systematic methodology for assessing cable condition through the use of survey tools and online and offline techniques. Some techniques are more applicable to certain cable types and we will look at the multitude of testing methods available and what each is capable of detecting in terms of ageing. We will also consider the future of cable maintenance, changing maintenance approaches, new testing and monitoring techniques, and sustainability.

The course is applicable to all voltage classes and will address cable types including self-contained fluid-filled, PILC/MIND, PE, XLPE, TR-XLPE and EPR cable designs, as well as the associated accessories and cable system components. Doble encourages participants to bring their unique real-world problems for discussion.

Learning Outcomes

Upon completion of this course, the participant will be able to:

- Learn the four types of cable ageing phenomena

- Identify the types off defects that can be introduced during cable manufacture and installation

- Identify the advantages and disadvantages of online versus offline techniques

- Appreciate the pros and cons of different diagnostic techniques applicable to the whole cable system

- Gain an understanding of the international best practice documents which exist

- Know the different approaches to maintenance strategy

- Learn some of the new emerging technologies which may help cable maintenance engineers in the future

Content

Key features of cable feeder maintenance

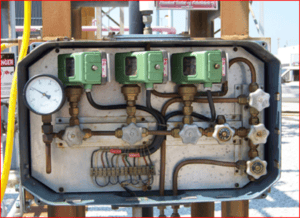

- Elements of a cable circuit; cable & accessories, bonding, earthing

- Cable design and materials

- Installation environment

Considerations for cable joints and terminations – quality of installation and testing

Common defects in cable

- Manufacturing defects

- Installation issues; cable & accessories, bonding, earthing

- Importance of commissioning testing and options

Cable ageing process

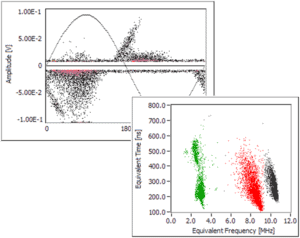

- Ageing processes; thermal, electrical, chemical, mechanical

- Resultant defects and detection methods

International best practice guides

Types of cable tests during operation

- Visual assessment and environmental factors

- Survey tools

- Online and offline testing

Future of cable maintenance

- New testing approaches

- Shifting maintenance approaches; TBM, CBM, RCM

- Digitalization

- Sustainability

Title: Cable Ageing, Diagnostics and Maintenance

Duration: Three Days

For information on scheduling a course at your location or for other questions, please contact sales.