The Digital Shift: Navigating the Transition from Analog to Digital

Companies – vendors like us, asset owners, and contractors – in the power industry are advancing together with new technologies and trends. The world of protection relaying is included in this advance which is changing the game on operational technology (OT) areas within organizations.

Adoptions of increased protection system automation – particularly IED schemes based on IEC 61850, for example – are toppling the high wall that has traditionally separated network communications and system protection. Interdisciplinary teams are collaborating like never before – communications people are talking protection and protection people are talking communications!

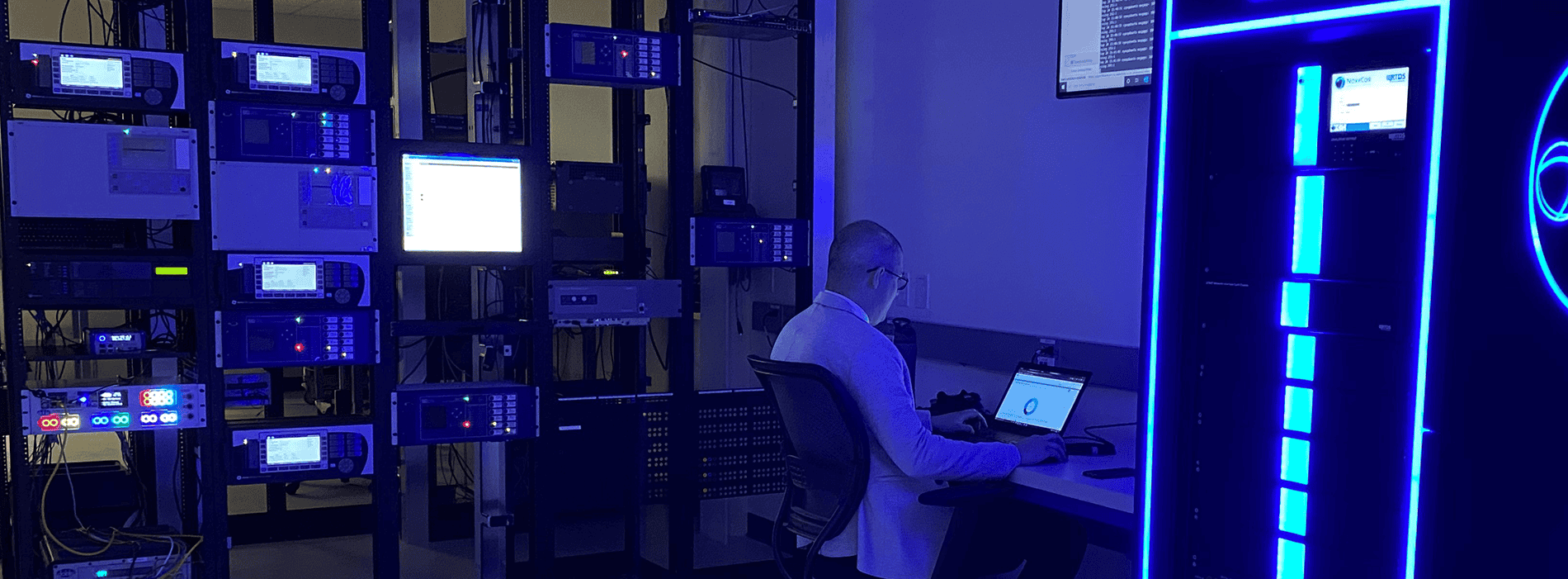

In Doble Engineering, there is a commitment to be at the forefront of advancements in the electric power industry. For this reason, we invested in a relay laboratory at our headquarters in Marlborough, Massachusetts. We use this facility to validate that our line of protection products is ready for the rigors that customers will put them through when testing relays regardless of type or vintage.

In our laboratory, we have CO-9, KD-10, IAC53, IRD9, and many other models/styles of EM relays. Our relay testing instruments, and software applications are prepared for technicians whether they’re well-versed in the art and science* of EM relay testing or not. The lab gives us workspace to perform manual and automated test methods that replicate how customers with different experience levels and preferences can use our products to maintain and calibrate such devices as these successfully in their jobs.

Our laboratory also hosts a selection of MP relays. With these devices, we validate communications with the test software on the PC and perform auto-population and verification of settings along with other checks to ensure we are providing what is needed to start testing in an automated way. Ultimately, we want technicians to use the additional functions we’ve included for MP relay testing as intuitively as all the other software tools we provide that pertain to EM relay testing.

Regarding digital protection and control, the laboratory lets us build schemes involving various parts of the electrical power system (Generation, Transmission, and Distribution) all framed within the IEC 61850 standard. Digitalization enables us to do robust simulations of all possible coordination scenarios.

Working with digital relays is easy, that is, if we look at them like computers that simply mount into racks and have their power supply wired and a few Ethernet or fiber optic cables connected. In a bit of a contrast to EM and MP relays, IEDs reduce the contents of our carry bag to just one or two Ethernet cables that are needed for configuring and testing.

They say that life is not easy and that’s true in the world of protection relays. In the digital context, performing tests requires a strong understanding of IED settings for functions like publishing and subscribing to GOOSE messages; conforming to communication architectures; switching (PRP – HSR, VLANs); synchronizing to master clock time references (PTP Profile, Domain #); receiving SV from MUs (61850 9-2 LE or 61869-9); identifying IP addresses, MAC addresses, multicast parameters, and other matters involving the networks where digital relays reside. Without cables to trace, seeing what’s going on and knowing where to find issues and how to resolve them is complicated. It’s when solutions are needed that Doble develops the necessary tools to help customers verify their digital P&C implementations.

In our relay lab, we have a Real-Time Simulator where the hardware in the loop is made for MP relays and IEDs. For digital applications, we can simulate up to 48 SVs and we use the digital multimeter/network analyzer we developed to see numerous pieces of information about the network. The breakthroughs we’re making add to the many reasons why our relay lab has been so beneficial to us and our customers.

The challenges of implementing our lab have given us insights into what customers experience when they build theirs. Everyone in this industry is learning, and we all are doing the best job possible to keep pace with continual technological advancements in our industry. The investments we’ve made in our relay lab reflect our commitment to lead and elevate our ability to work hand in hand with customers. It doubles as a training center and provides workspace where we develop and refine solutions to help customers overcome the challenges they face, and we do as well, regarding relay testing, implementing automation based on IEC 61850, or even embarking on entirely virtual protection and control.

Additional Information:

- Keywords: EM (Electromechanical), IED (Intelligent Electronic Device), GOOSE (Generic Object-Oriented System Events), MU (Merging Unit), MP (Microprocessor), PRP (Parallel Redundancy Protocol), HSR (High-Availability Seamless Redundancy), VLAN (Virtual LAN), PTP (Precision Time Protocol).

- *Book of “The Art & Science of Protective Relaying”; C. Russell Mason

- Doble Protection Testing Products