Réseaux sous contrainte, partie 4 – Les services d’électricité misent sur l’IA pour détecter les défaillances avant qu’elles ne se produisent

Comment la maintenance conditionnelle évolue du réactif au prédictif et pourquoi cela est plus crucial que jamais.

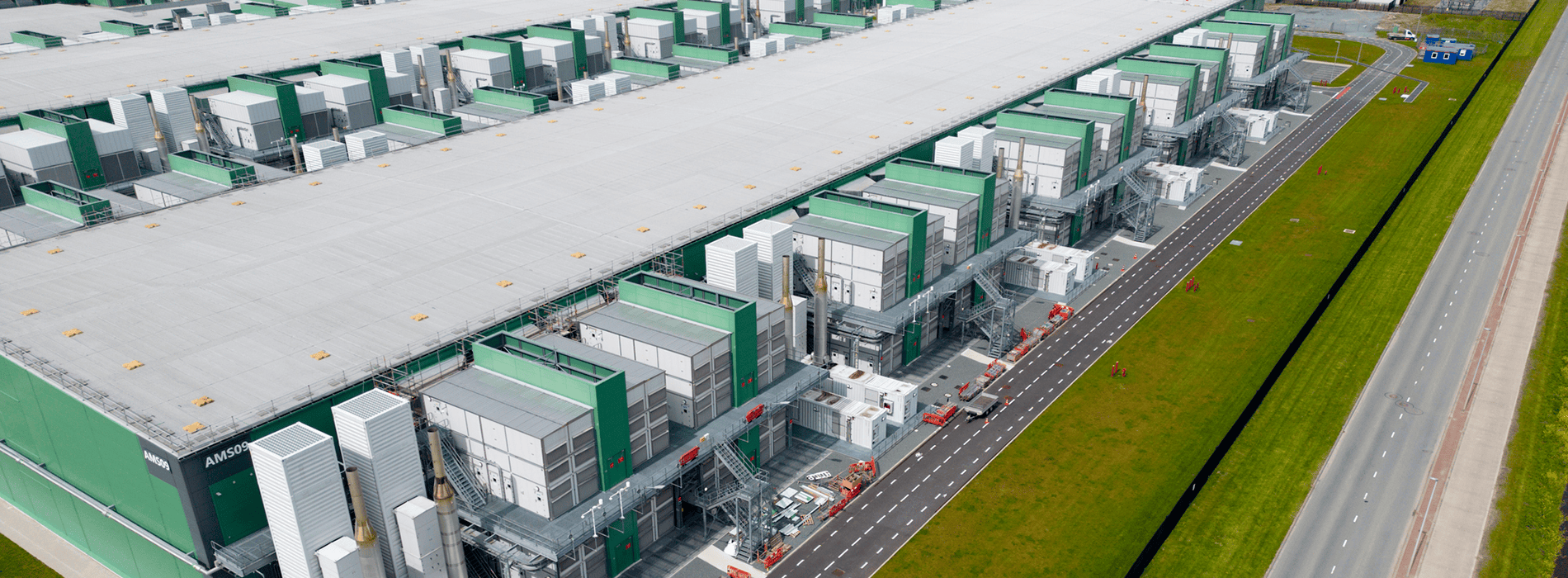

L’intelligence artificielle stimule une demande énergétique exponentielle et met en évidence la réelle fragilité de nombreux systèmes de réseau. Le résultat ? De nombreux services d’électricité reconsidèrent non seulement leurs approches de planification des infrastructures, mais également leurs stratégies de maintenance.

Alors que les services d’électricité doivent composer avec des pénuries de transformateurs, une infrastructure vieillissante et une demande énergétique à la fois fluctuante et constante, beaucoup misent sur la surveillance d’état et les diagnostics prédictifs basés sur l’IA pour anticiper les défaillances éventuelles. Dans toute l’Amérique du Nord, les opérateurs se tournent vers la maintenance conditionnelle et prédictive, renforcée par l’IA, pour identifier les risques plus en amont, intervenir plus rapidement et optimiser la protection en mobilisant moins de ressources.

Il s’agit de passer d’une approche réactive à une stratégie de prévention optimisée. Et pour de nombreux services d’électricité, cela s’avère déjà essentiel.

De la maintenance planifiée à une approche prédictive

Historiquement, la maintenance reposait principalement sur un cycle temporel : vérifier les équipements à intervalles réguliers de X années et remplacer les composants après Y heures de fonctionnement. Mais comme la demande dépasse la capacité et que l’infrastructure vieillit, les services d’électricité ne peuvent plus se permettre d’opérer selon des calendriers rigides.

Les diagnostics prédictifs basés sur l’IA changent la donne. En intégrant des données sur le comportement à long terme des actifs et des informations de surveillance en temps réel, les opérateurs peuvent exploiter l’IA pour identifier les signaux d’alerte précoce et anticiper avec une bien meilleure précision les risques de défaillance.

Ce changement n’est pas hypothétique. Les services d’électricité constatent déjà des résultats. Certains évitent les remplacements inutiles, d’autres évitent complètement les pannes. Et presque tous améliorent leur capacité à établir des priorités pour savoir où et quand agir.

Des outils plus performants pour des décisions plus éclairées

Pour que l’IA prédictive fonctionne, elle a besoin d’une base de données de diagnostic de grande précision. C’est là que la surveillance d’état intervient.

Chez Doble, des solutions telles que les moniteurs Calisto™ DGA, les moniteurs de traversées et de décharges partielles doblePRIME™ offrent la visibilité en temps réel nécessaire au fonctionnement de l’IA. Associés à des plateformes d’analyse des équipements, les services d’électricité peuvent automatiser les alertes, suivre les tendances au sein de leur parc d’équipements et développer des modèles d’apprentissage automatique pour éclairer les décisions.

Ce genre de visibilité produit un impact quantifiable. En passant des tests statiques au suivi en continu de l’état des équipements, les services d’électricité optimisent leur efficacité :

- Identification anticipée des risques émergents

- Plannings d’entretien et d’inspection mieux ciblés

- Réduction des temps d’arrêt et des coûts d’entretien

- Allongement de la durée de vie des équipements, notamment pour les parcs de transformateurs soumis à des contraintes

Préparer l’avenir

La surveillance d’état basée sur l’IA n’est plus une simple perspective. Il s’agit d’une stratégie opérationnelle contemporaine qui aide les services d’électricité à optimiser les ressources, à réduire les temps d’arrêt et à prévenir les instabilités du réseau avant qu’elles ne se produisent.

Mais les outils numériques, à eux seuls, ne suffisent pas à résoudre les défis posés par des transformateurs vieillissants, des postes électriques saturés et des infrastructures obsolètes, conçues dans un contexte technologique d’une autre époque. Alors que les tensions sur le réseau s’intensifient, les services d’électricité doivent associer des diagnostics plus intelligents à une modernisation qui n’a que trop tardé. Dans notre prochain article, nous examinerons comment les pénuries de transformateurs, les contraintes sur les réseaux de transmission et les délais liés à l’obtention des permis constituent désormais les principaux freins à la fiabilité de l’intelligence artificielle, ainsi que les mesures que les opérateurs électriques peuvent prendre pour s’y préparer.

Chez Doble, nous accompagnons les services d’électricité dans l’exploitation de la puissance de l’IA, en nous appuyant sur des diagnostics d’experts, des décennies de savoir-faire sur les parcs d’équipements et une assistance technique fiable, indispensables pour maîtriser les défis actuels et anticiper les besoins de demain.

Informations complémentaires :

- Réseaux sous contrainte : l’IA et la fiabilité du réseau, partie 1 – La crise énergétique provoquée par l’IA : Comment les centres de données redéfinissent-ils la fiabilité des réseaux électriques ?

- Réseaux sous contrainte, partie 2 – Comment les services d’électricité peuvent-ils anticiper les contraintes énergétiques liées à l’IA avant qu’il ne soit trop tard ?

- Réseaux sous contrainte, partie 3 – IA contre IA : L’intelligence artificielle peut-elle résoudre la tension qu’elle impose au réseau ?