Two Hooks Are Better Than One

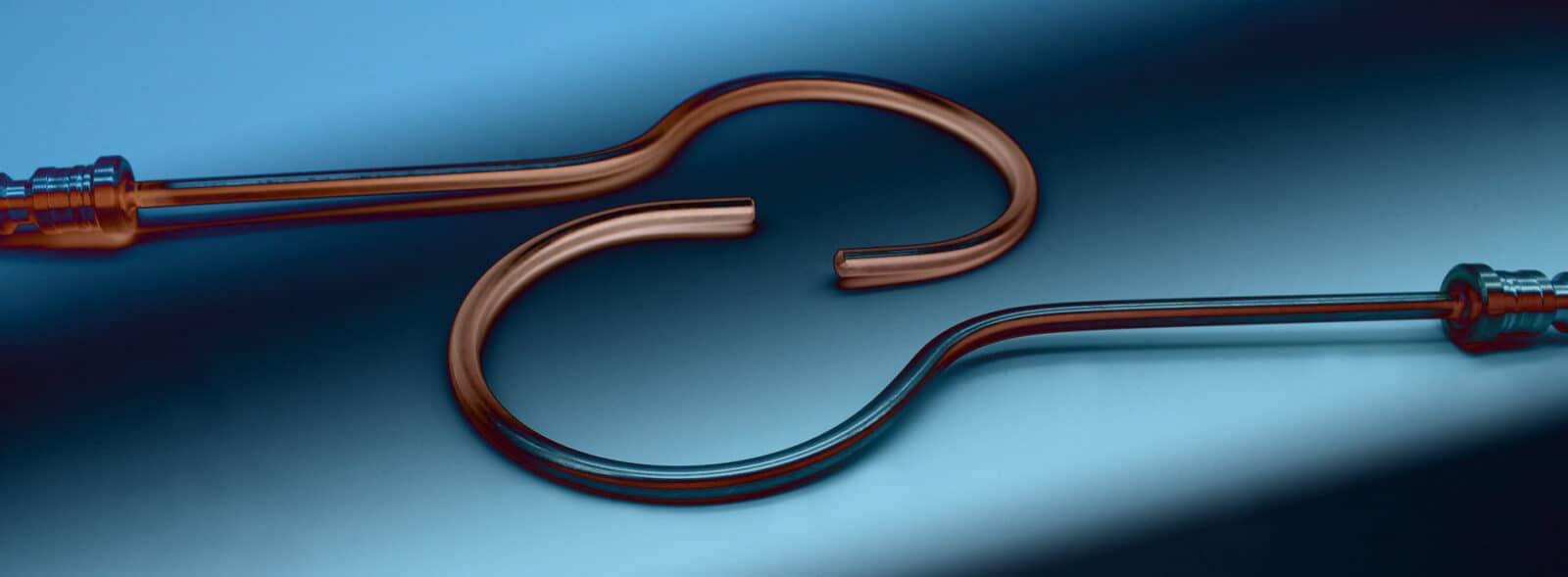

Two is better than one. Seems like an easy enough concept that most of us can appreciate. But, did you know that Doble’s M7100 HV Asset Analyzer is the first and only test set to have two dual-function 12kV source and measure leads? These leads are used for tests that require a high voltage source, with the most common use being power factor (PF) testing. Because of Doble’s long history of innovation with Power Factor testing, it is often referred to as the “Doble Test”.

How has the M7100 evolved?

An HV test instrument uses a large lead with a hook or clamp on the end that can deliver up to 12kV for power factor, tan-delta, knee points and excitation current tests. This same high voltage source is used to excite apparatus in support of other functions such as partial discharge, corona inspection and burden tests. The single-lead system is a versatile tool to have for many of the most important HV apparatus tests.

Doble’s M7100 doesn’t stop there, as it has also added a second HV lead and added the ability to measure. Combined with advancements in switching and measurement technology, users can use two leads to energize up to 12 kV independently or measure—effectively turning one, or both of the HV test leads into a measurement lead.

How much faster are two hooks than one?

The quick answer is a lot— users can cut the time of doing a complete test on a transformer by up to two-thirds. Given the number of extensive tests most power companies conduct today, which require going up and down ladders and unhooking and hooking HV leads, a two HV-lead test instrument creates an extreme time-saving advantage because the ability to easily shift between sourcing and measuring allows the measurement leads to stay in place.

The table below compares a handful of test scenarios, proving that two HV leads can cut hours off an apparatus test.

HV Transformer Turns Ratio Testing |

||

| Single HV Lead | Dual HV Lead | |

| Excitation Current Test | 2 Hours | 30 Minutes |

| Two Winding Transformer Overall Test | 15 Minutes | 3 Minutes |

| Complete Bushing Power Factor Test Sequence (C1, C2, C1+C2, Inverse C1) | 10 Minutes | 3 Minutes |

Simplifying Test Procedures

HV testing skills are getting harder to maintain as the job becomes increasingly complex, requiring testing technicians and engineers to wear multiple hats. Traditional HV testing requires users to fully understand a variety of circuits, their configurations and idiosyncrasies in order to perform correctly.

A two-lead system removes much of that hassle and learning curve. Thanks to the automation of the M7100, successful test completion simply requires an understanding of where to put the leads, as the test instrument will shift the circuit automatically. Even further, the simple setup reduces most of the errors made during lead placement and movement—which is where most mistakes tend to occur.

The Safer Alternative

The more a user must go up and down ladders or use a bucket truck, the greater the chance of injury. Similar to how three-phase LV test instruments (TTR, winding resistance) replaced single-phase test instruments, the M7100 can reduce the number of trips up and down the ladder by as much as two-thirds – deeming it a much safer alternative to traditional, single HV-lead test instruments.

So, is two better than one? Absolutely, and taking advantage of the latest technology will save time, money and help prevent workplace injuries.

NEXT STEPS

- Learn more about the Doble M7100 and how you can drive efficiency and safety in the field today.