EMI Diagnostics: Isolated Phase Bus

Electro Magnetic Interference (EMI) diagnostics is the precise measurement and analysis of conducted and radiated signals produced by electrical and mechanical defects in high voltage systems. An EMI measurement provides a condition assessment of the entire system – in the case of rotating machines this includes the isolated phase bus (IPB), as well as the generator, exciter and breakers connected to it. The measurement can be performed in one of two ways:

- Frequency domain using the EMI spectrum or signature.

- Time domain using the EMI emission at a single frequency.

One of the big advantages of this technique is that data can be collected without the need for an outage and with thousands of successful EMI tests performed globally over the past 40 years, it has a track record of reliability. A permanently installed coupler is not necessary to collect EMI data; a split core radio frequency current transformer (RFCT) can simply be placed around a suitable earth connection. A skilled test engineer can collect all the required data in about one hour.

Using EMI diagnostics to supplement partial discharge testing

As an example, in preparation to bring a generator back into service after a rewind, the local site engineers performed conventional time-of-flight partial discharge (PD) testing. These tests found increased PD activity on one phase and indicated that the signals may originate from inside the generator: however, the location information was inconclusive. Doble engineers performed additional EMI testing to determine if the PD was genuine, and if so, to locate the source.

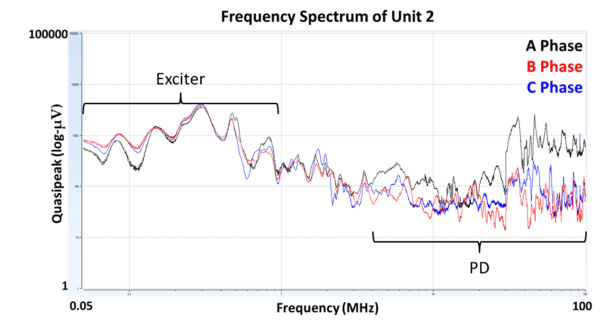

The EMI frequency spectrum shows significant evidence of PD activity, especially in the IPB region of the spectrum on the A phase of the generator.

Further analysis in the time domain confirmed no PD activity associated with the generator. The analysis using Phase Resolved Partial Discharge (PRPD) plots did show several floating potentials, which are indicative of damaged IPB insulators or insulators not making good electrical contact with the centre conductor.

Based on this evidence, a mini-outage was scheduled to examine the condition of the IPB insulators close to the generator terminals. Clear evidence of PD activity was observed on both the insulator heads and centre conductor on the A phase; whereas no such evidence was found in either B or C phases which confirmed the source of the PD signals.

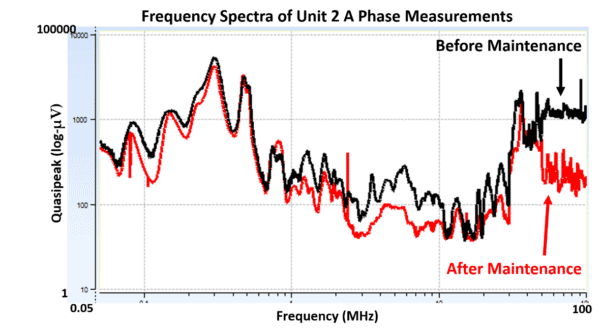

Following this discovery, site engineers cleaned the insulator heads and centre conductor. Subsequent EMI surveys in the following months, taken at similar loads to the original testing, showed that while discharge activity had not been eliminated, it had decreased. The client was satisfied with the increased knowledge of the ongoing discharge activity showing that the level remained insignificant. It also highlighted to them the importance of IPB maintenance activities, which had been frequently postponed during major outages.

As this case study shows, EMI diagnostics is a powerful tool for performing condition assessments on rotating machines, which can not only detect defects but also locate the source. This can lead to shorter outages for interventions and quicker, more targeted repairs.

As this case study shows, EMI diagnostics is a powerful tool for performing condition assessments on rotating machines, which can not only detect defects but also locate the source. This can lead to shorter outages for interventions and quicker, more targeted repairs.

ADDITIONAL RESOURCES:

- Learn More: EMI Diagnostic Testing and Consulting Services

- Further Reading: Use of Conventional and Unconventional Techniques to Identify Partial Discharge Activity in Isolated Phase Busbars