Phenix Technologies has established worldwide recognition as the leading manufacturer having supplied more Motor Test Systems than all other manufacturers combined. Not only does our engineering expertise and manufacturing capabilities provide solutions for customers who may need a custom designed system for special requirements, Phenix Technologies continues to introduce new innovations and technology that leaves our competition behind. When your electric motor testing needs require complete system design and installation, from concept to commissioning, Phenix Technologies is ready to be your project partner.

Perform testing on all types of:

- AC and DC motors

- Traction motors

- Synchronous motors

- Induction motors

- Shunt-, Compound-, and Series-Wound motors

Our range of options for High Power Motor Testing include:

- AC, DC, or AC/DC test systems

- Medium or low voltage input options

- Output power up to 10,000 kVA

- Configurations that allow testing of a 10,000 horsepower motor at full load and 50,000 horsepower at no load

- Manual operation, advanced control systems, fully automated testing, custom software solutions, database and report generation

- Precision voltage regulation with the Phenix Column type Variable Transformer

- “R2” design allows full voltage regulation without interruption which means the motor does not slow down for tap changes

- Highly accurate Voltage, Current, Power, Watts (including Kilowatt-Hours), Vibration, Temperature, and Speed measurement

- Commissioning and training to provide your operator with the information and resources they need for efficient and safe use of your investment

Do you want to run test motors? Do you want to load test motors? What is the highest HP you plan to run?

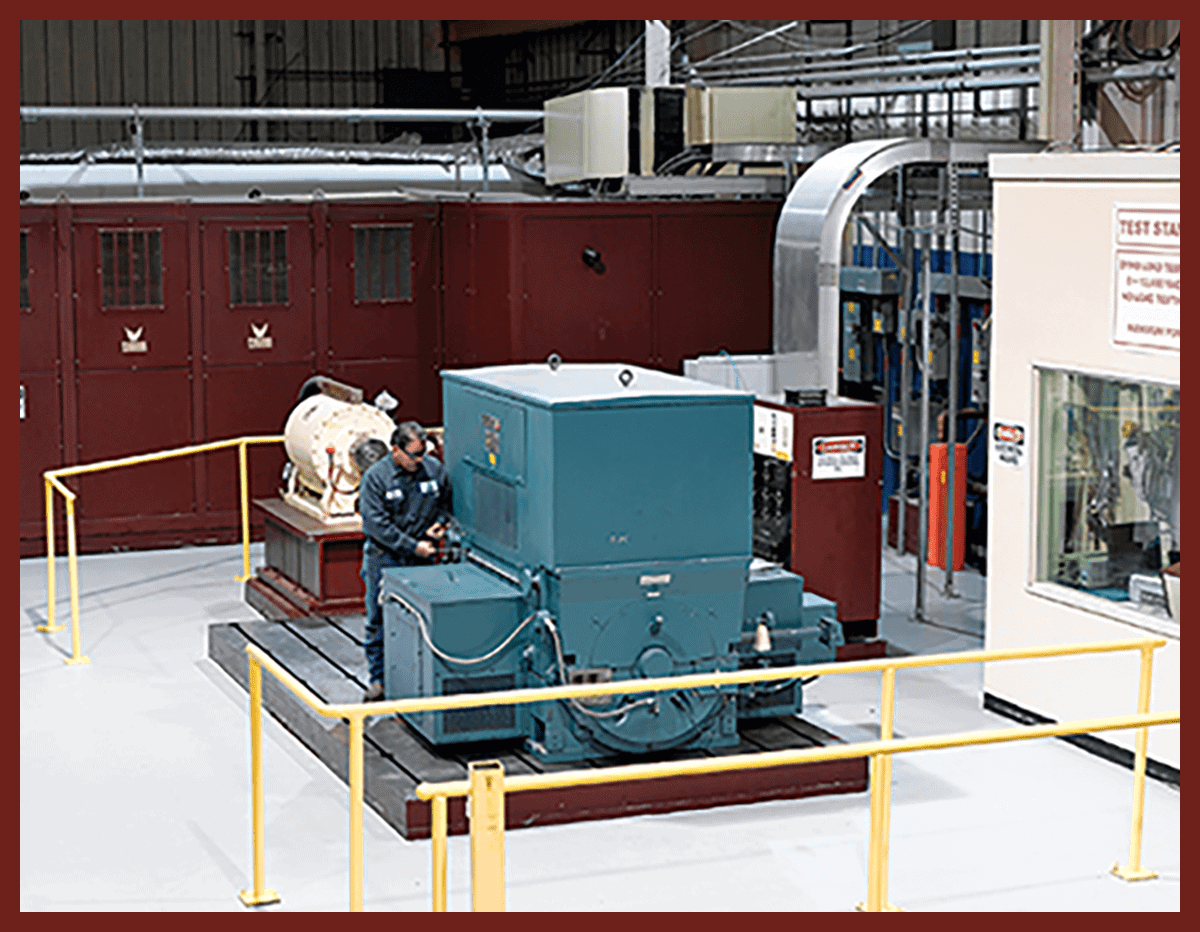

Phenix Technologies Electric Motor Test Systems are in operation around the world, providing exceptional service to Motor Manufacturers, Motor Service Shops,

Industrial Plants, Electric Utilities, Government Installations.

For over 40 years Phenix Technologies has established worldwide recognition as the leading manufacturer of Motor Test Systems. We have supplied more Motor Test Systems than all other manufacturers combined. Not only does our engineering expertise and manufacturing capabilities provide solutions for customers who may need a custom designed test system for special requirements, Phenix Technologies continues to introduce new innovations and technology that leaves our competition behind. The Phenix Technologies’ team manufactured and delivered the world’s largest Motor Test System and Core Loss Tester.

Phenix Technologies offers a complete line of electric motor test systems for load and no-load testing of all types of AC and DC motors, traction motors,

synchronous motors, induction motors, shuntwound, compound-wound, and series-wound motors. We have test systems available for testing fractional up to 50,000 HP motors.

When your electric motor testing needs require complete system design and installation, from concept to commissioning, Phenix Technologies is ready to be your project partner.

Each motor test system is equipped with all of the controls, power supplies, metering, and safety/protection devices necessary for efficient testing. Our heavy-duty steel cabinet has removable panels, lifting eyes, slots for fork lifting, and meets NEMA 1 standard for indoor installation. Control panels are primed and painted with a high quality polyurethane gloss finish and have permanently imprinted indicator labels. Our ISO9001 compliance ensures optimum standards of quality are met from design through production and verified in final pre-shipment testing procedures.

- AC, DC, or AC/DC test systems

- Medium or low voltage input options

- Output power up to 10,000 kVA

- Configurations that allow testing of a 10,000 horsepower motor at full load and 50,000 horsepower at no load

- Manual operation, advanced control systems, fully automated testing, custom software solutions, database and report generation

- Precision voltage regulation with the Phenix Column Type Variable Transformer

- “R2” design allows full voltage regulation without interruption which means the motor does not slow down for tap changes

- Highly accurate Voltage, Current, Power, Watts (including Kilowatt-Hours), Vibration, Temperature, and Speed measurement

- Commissioning and training to provide your operator with the information and resources they need for efficient and safe use of your investment

The following information will assist you in choosing the power supplies, features, and options for a motor test system that meets your specific needs. For additional assistance, please consult one of Phenix Technologies Sales Representatives.

The Phenix Column Type Variable Transformer – Leveraging Your Investment in Test Equipment…

Whether you are an OEM or are in the electric motor repair business, the key to keeping your business running smoothly is reliable equipment. No matter whether you have to test a 50 HP or a 50,000 HP machine, Phenix Technologies Motor Test Systems are synonymous with reliability. The heart of any high power test panel is the voltage regulating system. Phenix Technologies Column Type Variable Transformers (CTVT) have a proven record of performance of over 40 years of service in hundreds of high power motor test field installations. With no sliding contacts to wear or bind, and no sensitive power electronics that can fail leading to expensive winding damage, the Phenix CTVT has become the workhorse of the large motor testing industry.

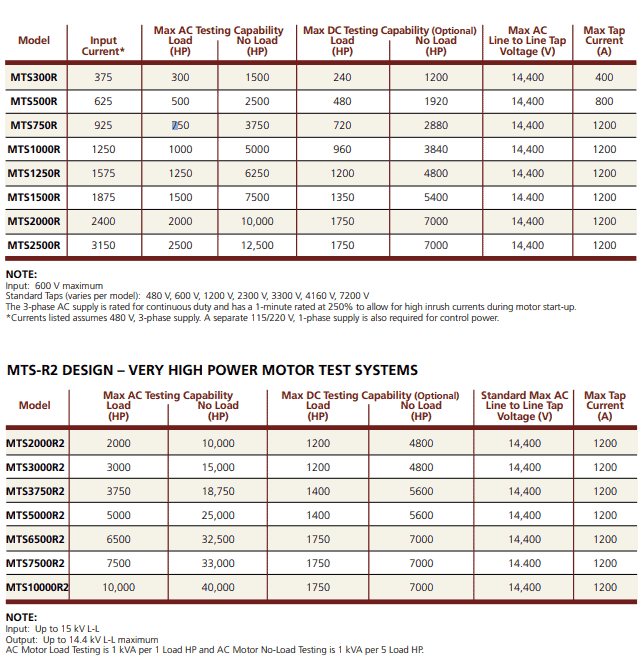

Standard MTS-R Series – Unmatched Reliability and Performance…

Phenix’s standard high power Motor Test Set product line utilizes the CTVT for full range voltage regulation on all output voltage taps. With a turn-to-turn voltage resolution of approximately 0.15%, all Phenix high power Motor Test Sets demonstrate an impressive ability to target and maintain the correct test voltage at the output terminals. Our standard line of high power Motor Test Systems can be designed to operate at 50 or 60 Hz, from any low voltage service up to 600 VAC, at power levels up to 2,500 kVA. The Standard MTS-R Series is capable of performing full load tests on motors rated up to 2,500 HP, and no load tests on

motors rated up to 12,500 HP.

MTS-R2 Series – When “Serious” Power is Required…

With over 10 years of service history behind them, the Phenix MTS-R2 series of very high power Motor Test Sets delivers the power to test even the largest electric motors. With the Phenix CTVT applied as the basic voltage regulating element, combined with a multi-tap step-up transformer and a computer controlled on-load switching network, these units are capable of providing uninterrupted voltage from 0 up to 14.4 kVAC. When starting motors in excess of 10,000 HP, maintaining an uninterrupted, regulated voltage during startup is essential to avoiding high inrush currents that could lead to tripping of current limiting devices within the distribution network.

Our MTS-R2 series can be designed to operate at 50 or 60 Hz, from any medium voltage service up to 14.4 kVAC, at power levels up to 10,000 kVA. The MTS-R2 Series is capable of performing full load tests on motors rated up to 10,000 HP, and no load tests on motors rated up to 50,000 HP.

Precise, Balanced Voltage Control – A Must When Making Efficiency Measurements…

Proper efficiency measurements require a balanced set of low distortion, three-phase voltages. Independent, automated phase voltage balancing is available as an option on all Phenix standard MTS-R models, and comes installed as standard equipment on all MTS-R2 series units. With the independent phase balance option installed, you won’t have to make any explanations to your customers to get them to accept the test results for motors tested with unbalanced phase voltages, or waste your time arguing with your electric service provider about your service quality. With ever increasing world energy costs, and a global obligation for all of us to become more wise stewards of the environment, your business can use the power of a Phenix Motor Test System to convince your customers that you are serious when it comes to proving the quality and efficiency of your products and services.

The following testing capabilities are approximate and depend on type and style of the motor to be tested.

Phenix Technologies Motor Test Systems will typically run 1 HP per kVA of power fully loaded and 5 HP per kVA no-load. For example, a 1000 kVA motor test system is capable of approximate full load testing of a 1000 HP motor and no-load testing of a 5000 HP motor.

A selection of control and metering packages are available which greatly enhances the function, safety, and automation of each PHENIX motor test system.

All High Power Motor Test Systems are equipped with Microprocessor Controls and a Human Machine Interface (HMI) that processes and displays control functions and meter readings.

User-friendly, PHENIX WINMTS software is provided for complete database storage of customer and motor information as well as test result storage, display, and printout.

Future periodic calibration of the metering is easily accomplished by one of our PHENIX service technicians keeping your motor test system at top performance

level for many years.

Standard Operating Control functions include:

- Main Power Breaker with indicator lamp

- Control Power Breaker and indicator lamp

- High Voltage ON and OFF pushbuttons/indicators

- Emergency OFF Mushroom pushbutton

- Security Circuit Interlock Open indicator lamp

- Ground Fault Reset pushbutton/indicator

- Raise and Lower Voltage pushbuttons/indicators

- Ramp Speed control

- Output Current Selector pushbuttons/indicators

- Tap Select Increase/Decrease pushbuttons

- HV Interlock Key-Switch

- Regulator Overload Protection

- Thermostatically controlled Cooling Fans/Cooling Fan Breaker with Indicator

When optional features or supplies are purchased, additional control features exist.

Combining the control system with our testing software creates a very user friendly system which provides complete documentation and reporting for each motor

tested. Two data bases are created, one of all of your clients and a second of all motors.

*Software is compatible with ACS motor shop software.

Precise Instrumentation

The test system has a complete instrumentation package for definitive measurement of electrical and physical characteristics of motors under test. All meters for AC and DC supplies are digital and displayed on the Human Machine Interface. High accuracy current transformers (CT), potential transformers (PT) and transducers are utilized for stability and a high degree of meter accuracy. All meters are calibrated with standards traceable to NIST/NRC and a calibration

sticker is affixed to the control panel faceplate.

The meter readings displayed are determined by the model of the test set and options selected.

The following meters have a 5-digit display and Accuracy is ± 0.5% of range ± Least Significant Digit (LSD)

Standard meters included for AC supplies

- Three-Phase AC Output Voltmeters displaying phases A-B, B-C, C-A

- Three-Phase AC Output Currentmeters displaying phases A, B, C

Optional meters

- DC Armature Output Voltmeter

- DC Armature Output Currentmeter

- DC Field Output Voltmeter

- DC Field Output Currentmeter

- DC Series Field Output Voltmeter

- DC Series Field Output Currentmeter

- Three-Phase Wattmeter

Optional physical measurement metering

- Vibration Monitor, Range: 0-10.00 mil (displacement)/ 0-0.3 in/sec (velocity), Accuracy ± 1% of Range +LSD

- Temperature Meter, Range: 0-200.0°C (32.0-392.0°F), Accuracy: ± 1°

- Tachometer, Range: 0-9,999 RPM, Accuracy ±1 RPM

Options Available

- Additional Output Taps

- AC Output Phase Balance Compensation for motor test systems with column-type transformers only

- AC Phase Reversal Switch

- DC Armature and Shunt Field Power Supplies

- DC Series Field Power Supply

- DC Armature Reversal Switch

- Synchronous Motor Shorting Switch

- Wattmeter

- Off-Zero Bypass

- Multi-function Input Meter displays voltage, current, power factor, kVA, kW

- Physical Measurement Instrumentation:

- Vibration Measurement

- Thermocouple Temperature Measurement

- RTD Temperature Measurement

- Tachometer/Optical Speed Measurement

- Computer and Printer

- Remote Control Console with Writing Desk and Interconnect Cables

- Remote Output Cubicle to locate output connection near test area

- Swivel Jib Boom for Output Leads

- Longer Interconnect Cables

- Dynamometer Interface / Control Mounting

Cables

Input: N/A (input connection is at main circuit breaker)

Output: 15’ (5 m) output cables for all supplies with twistlock connectors on one end and ring terminals with rubber boots on opposite end

Optional Remote Console: 15’ (5 m) interconnect cables

Optional Temperature Thermocouple: 15’ (5 m)

Optional Speed Measurement: 15’ (5 m)