Phenix Technologies has established worldwide recognition as the leading manufacturer having supplied more Motor Test Systems than all other manufacturers combined. Not only does our engineering expertise and manufacturing capabilities provide solutions for customers who may need a custom designed system for special requirements, Phenix Technologies continues to introduce new innovations and technology that leaves our competition behind. When your electric motor testing needs require complete system design and installation, from concept to commissioning, Phenix Technologies is ready to be your project partner.

Perform testing on all types of:

- AC and DC motors

- Traction motors

- Synchronous motors

- Induction motors

- Shunt-, Compound-, and Series-Wound motors

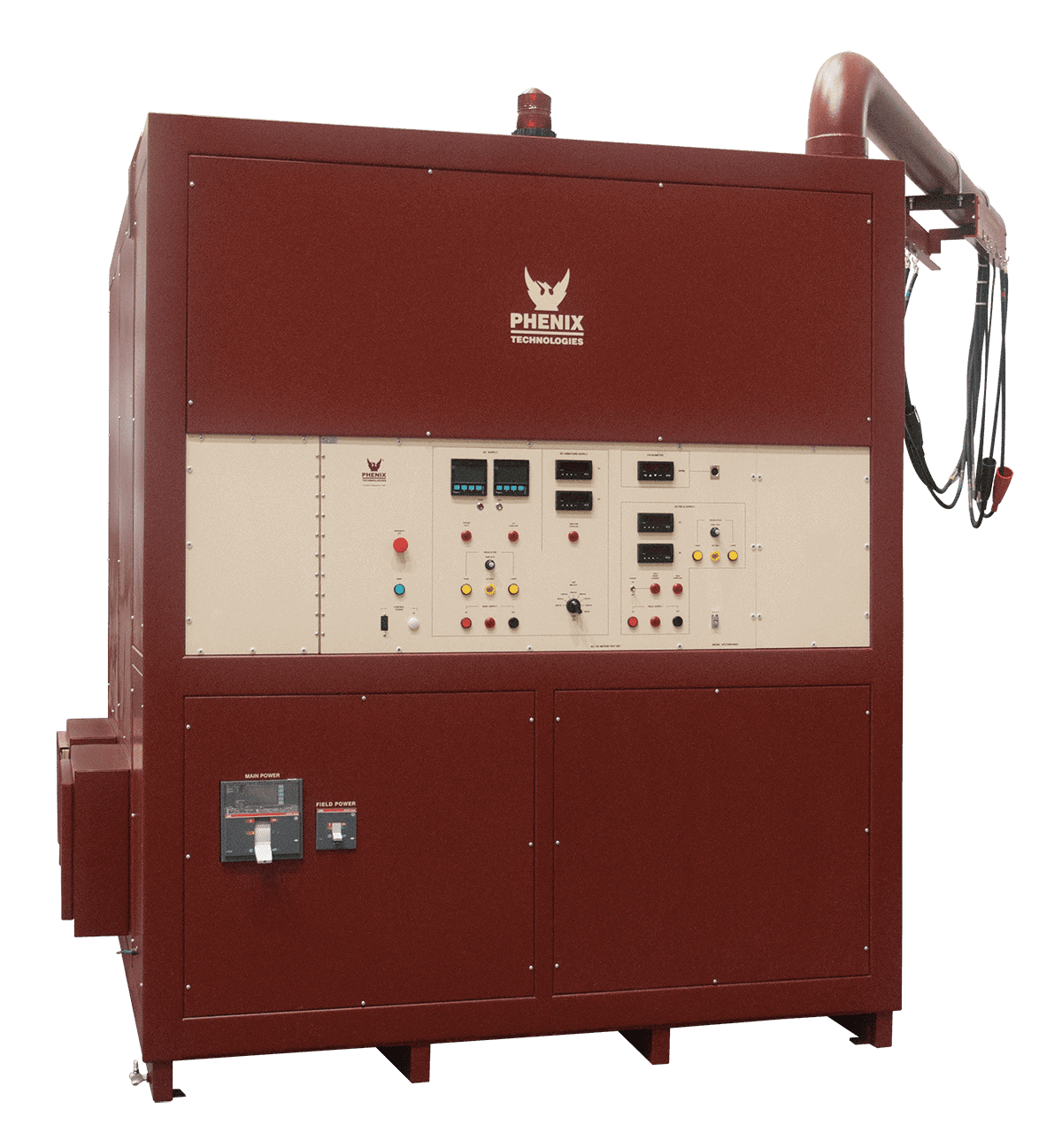

The MTS D-series is an economical motor testing solution with all controls and instrumentation in one cabinet, digital metering, pushbutton controls, and full voltage regulation.

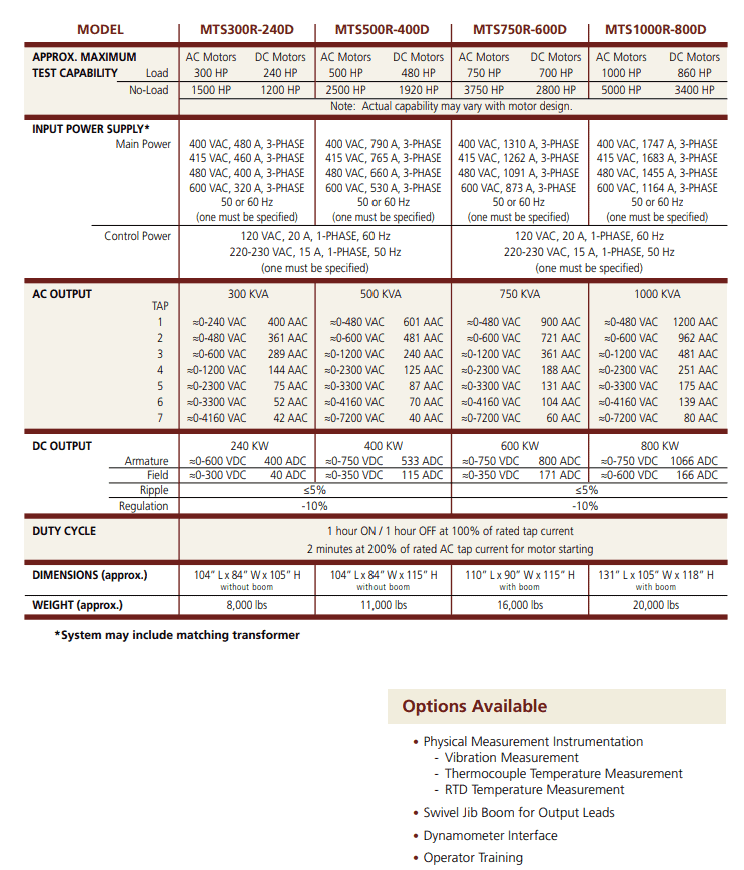

| Model | Rating |

| MTS300R-240D | 300 kVA |

| MTS500R-400D | 500 kVA |

| MTS750R-600D | 750 kVA |

| MTS1000R-800D | 1000 kVA |

Perform load and no-load testing on all types of AC and DC motors.

- Economical motor testing solution

- All controls and instrumentation contained in a single, industrial grade cabinet

- Full voltage regulation

- Main Circuit Breaker, Transient Protection, Output Overload Detection Circuits, Zero Start Interlock and Ground Fault Detection are standard features

- Control power circuit breaker with indicator

- A motorized screw and gear drive system is used for varying the output voltage on each tap from zero to 100% of full tap voltage

- Motor-controlled output tap selector switch

- Non-Contact Tachometer (RPM Meter)

- Unit is capable of drawing up to 200% of rated tap current for 2 minutes

- 5 Amp ground fault detection circuit with indicator and reset button

- Transient protection on all meters and relays including numerous built-in overload devices for complete unit and operator protection

- Synchronous Motor Shorting Switch

- Field undercurrent protection with bypass

- Emergency Off mushroom switch

- Each unit is equipped with a flashing red lamp when output is energized, external interlock, and warning circuit provisions

- Cabinet is provisioned for lifting via forklift or crane

- Jacks for twist-lock plugs are used on the AC and DC supplies with 15’ (4.5 m) output cables

- Operation/maintenance manual

- Convenient meter calibration

The AC supply includes 7 output voltage taps. The AC Power, DC Armature, and DC Field supplies are adjustable from near zero to 100% of rating.

To reduce high inrush currents, the output voltage is controlled by means of a Column-Type Variable Transformer designed and manufactured by PHENIX for this purpose. The PHENIX CTVT utilizes carbon rollers for current collection to eliminate the problems associated with sliding contacts. The PHENIX CTVT is designed with a low voltage difference (less than 0.7 V between adjacent turns to provide very high resolution on the output. The unique screw and gear drive system provides a superior and long lasting drive system.

Complete instrumentation is provided for definitive measurement of electrical characteristics of motors under test (3-phase metering, VM, CM, Watt, VARS, KVA, Power Factor). All metering is displayed on the meter module and digital panel meters, and have accuracy of +1.0% F.S. for each tap rating.

The control system combined with our testing software create a very user-friendly system which provides complete documentation and reporting for each motortested. WINMTS2 software is included.