Phenix Technologies has established worldwide recognition as the leading manufacturer having supplied more Motor Test Systems than all other manufacturers combined. Not only does our engineering expertise and manufacturing capabilities provide solutions for customers who may need a custom designed system for special requirements, Phenix Technologies continues to introduce new innovations and technology that leaves our competition behind. When your electric motor testing needs require complete system design and installation, from concept to commissioning, Phenix Technologies is ready to be your project partner.

Perform testing on all types of:

- AC and DC motors

- Traction motors

- Synchronous motors

- Induction motors

- Shunt-, Compound-, and Series-Wound motors

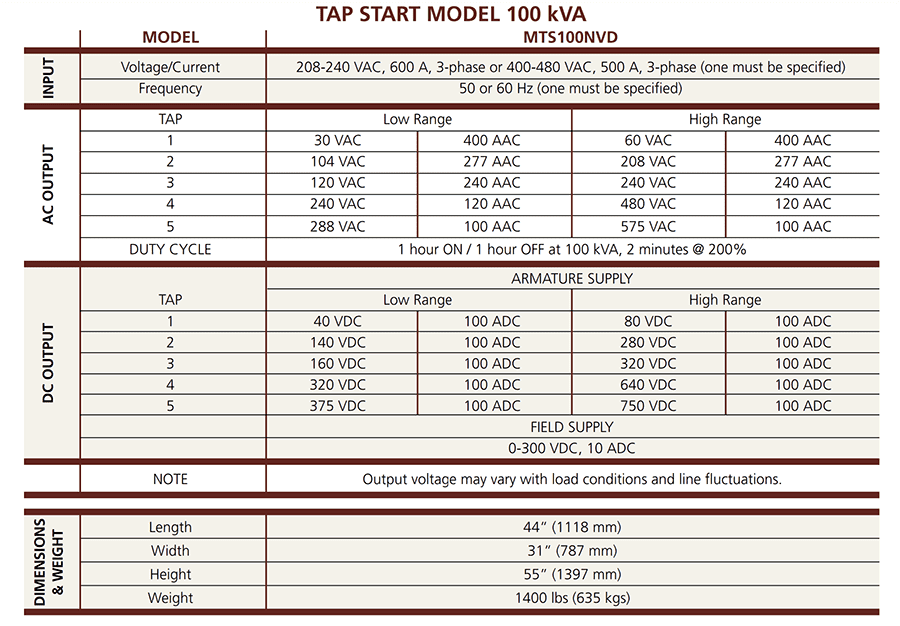

Phenix Technologies’ offers an economical testing capability for the small motor repair divisionor shop. All controls and instrumentation are contained in a single cabinet for complete load or no loading testing.

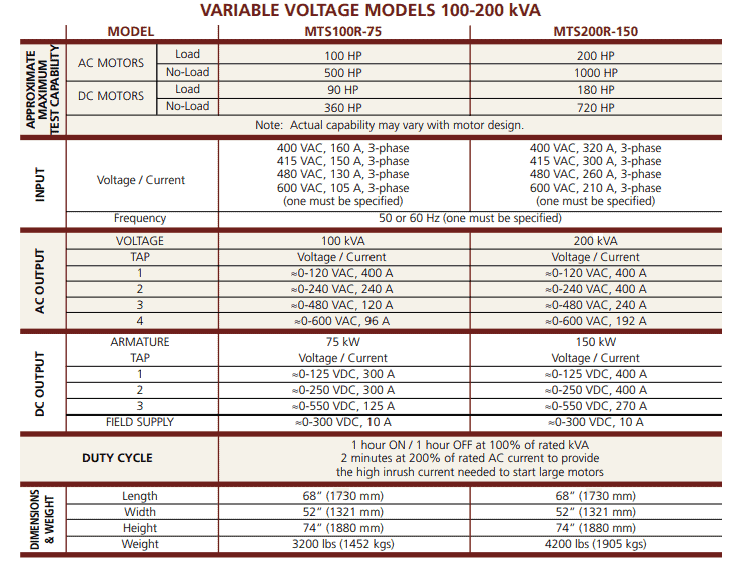

| Model | Rating |

| MTS100NVD | 100 kVA, Tapped, Non-Variable AC/DC Output |

| MTS100R-75 | 100 kVA Variable AC/DC Output |

| MTS200R-150 | 200 kVA Variable AC/DC Output |

Designed to provide test capability for smaller motors quickly and accurately.

PHENIX Technologies offers a complete line of motor test systems for AC, DC, synchronous and traction motors designed to test a wide range of horsepower and voltage classes. Many other applications requiring a continuously variable AC or DC power supply can also be satisfied by one of these units in an appropriate configuration.

Models Available:

- MTS100NVD

- MTS100R-75

- MTS200R-150

- Economical testing capability for the small motor repair division or shop

- All controls and instrumentation contained in a single, industrial grade cabinet

- Safety and protective features for complete load or no-load testing

Electric motors are a key component in most industrial applications. They account for about 66% of all the energy used in industrial applications with a lifetime energy cost totaling many times the original motor cost. Motor failures can lead to even higher cost in terms of lost production and efficiency. Industrial companies need effective motor management strategies to minimize overall motor cost. Motor rewinding by a well-equipped service facility reduces capital expenditures on motors while assuring reliable operation. The Phenix Technologies line of small motor test systems are the quality control center of a modern motor rewind and repair facility which insures rebuilt motor efficiency and quality.

Safety and Design Features

- Tapped, non-variable AC and armature outputs to start and run AC or DC motors

- Complete instrumentation is provided for precise measurement of electrical characteristics of motors under test (3-phase metering, VM, CM, WATT, VARS, KVA, POWER FACTOR). All meters are 4-digit LCD display and accuracy +/-1.0% Full Scale.

- USB Output Metering Interface to customer supplied compatible computer. Includes Windows based test software.

- Variable field supply

- Fused input power protection

- On / Off pushbuttons with indicator

- Flashing red warning lamp

- Thermal overload protection on main transformer

- Manual tap selector switch

- AC/DC output selector switch

- 15’ (4.5 m) output cables with storage hook

- Operation/maintenance manual

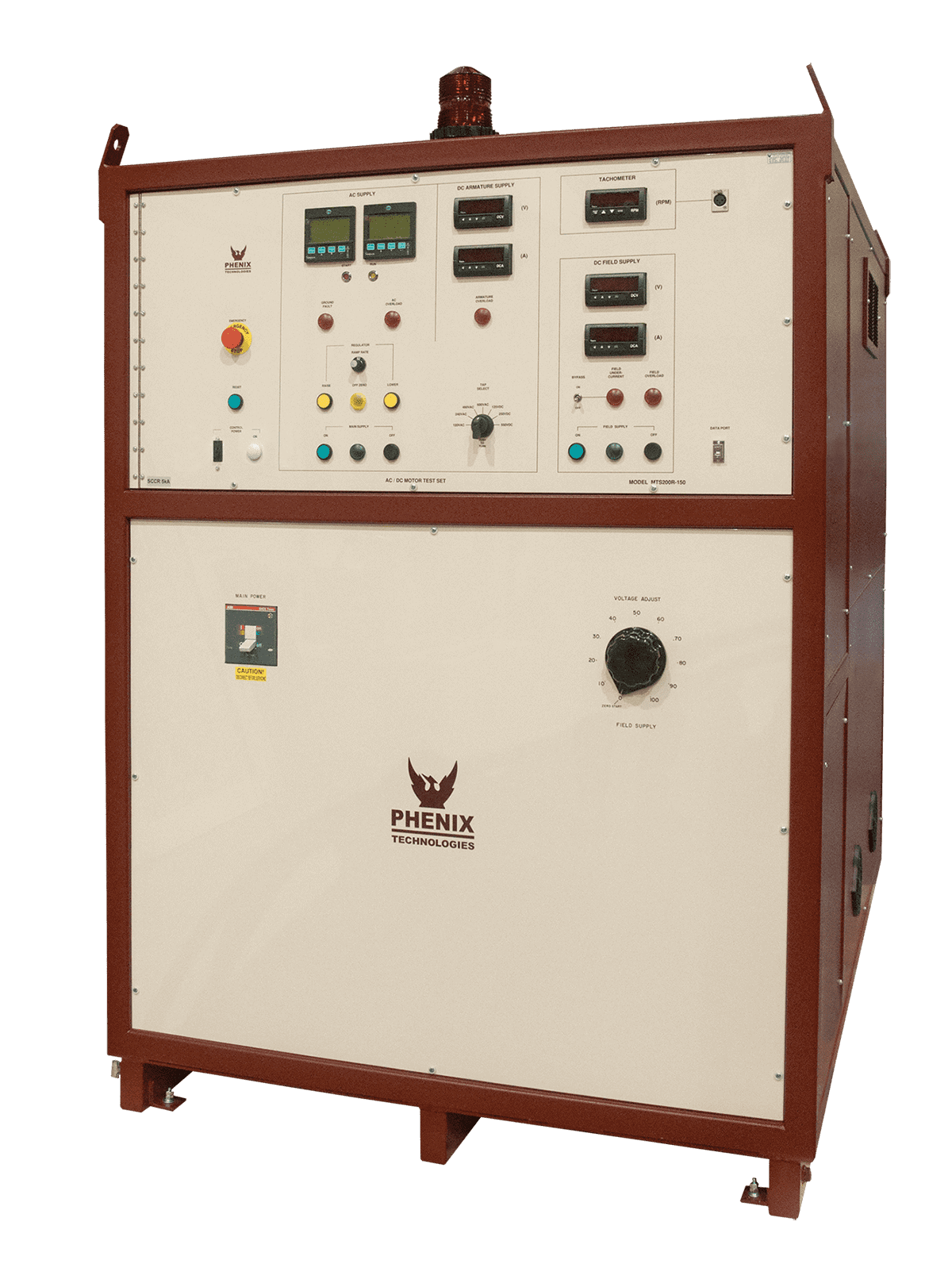

Safety and Design Features

- The AC supply includes four output voltage taps. The output on each tap is continuously adjustable from near zero to 100% of tap rating

- The DC armature and field supplies are adjustable from near zero to 100% of rating.

- Complete instrumentation is provided for precise measurement of electrical characteristics of motors under test (3-phase metering, VM, CM, WATT, VARS, KVA, POWER FACTOR). All meters are 4-digit LCD display and accuracy +/-1.0% Full Scale.

- USB Output Metering Interface to customer supplied compatible computer. Includes Windows based test software.

- Non-Contact Tachometer (RPM Meter)

- Main Circuit Breaker, Transient Protection, Output Overload Detection Circuits, Zero Start Interlock and Ground Fault Detection are standard features.

- The cabinet is provisioned for lifting via forklift or crane.

- Each unit is equipped with a flashing red lamp when output is energized, external interlock and warning circuit provisions

- Jacks for twist-lock plugs are used on the AC and DC armature supplies with 15’ (4.5 m) output cables.

- Operation/maintenance manual