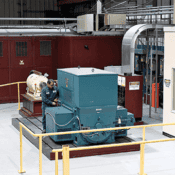

Phenix Technologies has established worldwide recognition as the leading manufacturer having supplied more Motor Test Systems than all other manufacturers combined. Not only does our engineering expertise and manufacturing capabilities provide solutions for customers who may need a custom designed system for special requirements, Phenix Technologies continues to introduce new innovations and technology that leaves our competition behind. When your electric motor testing needs require complete system design and installation, from concept to commissioning, Phenix Technologies is ready to be your project partner.

Perform testing on all types of

- AC and DC motors

- Traction motors

- Synchronous motors

- Induction motors

- Shunt-, Compound-, and Series-Wound motors

Excessive core loss negatively affects the efficiency and reliability of a motor. Core loss testing is necessary to insure the quality of a motor or motor rewind.

- Perform Core Loss Testing on Stators, Rotors and Armatures

- Perform Hot Spot Testing to identify localized shorted laminations that cause hot spots and insulation failure in a motor

- Fully automated with data acquisition

- True sine wave output ensures accurate and repeatable test results

- Simple set-up and operation

- Updated design with new controller

- 0.2% of reading transducer accuracy

- Ethernet interface

Testing Applications

- Perform core loss testing on stators, rotors, and armatures to insure the quality of a motor or motor rewind

- Perform hot spot testing to identify localized shorted laminations that cause hot spots and insulation failure in a motor

Models Available

- CL10B

- CL25B

- CL60B

- CL125B

- CL300B

- CL500B

- Fully automated with data acquisition

- True sine wave output ensures accurate and repeatable test results

- Simple set-up and operation

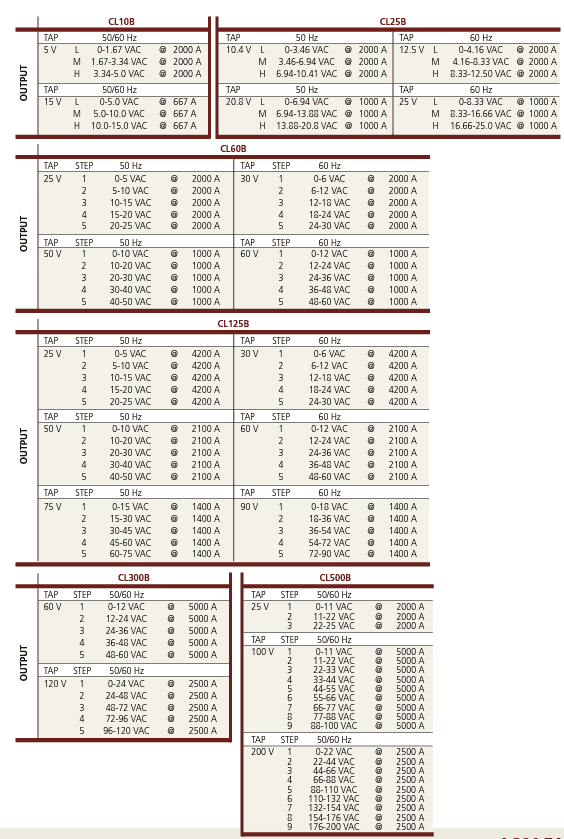

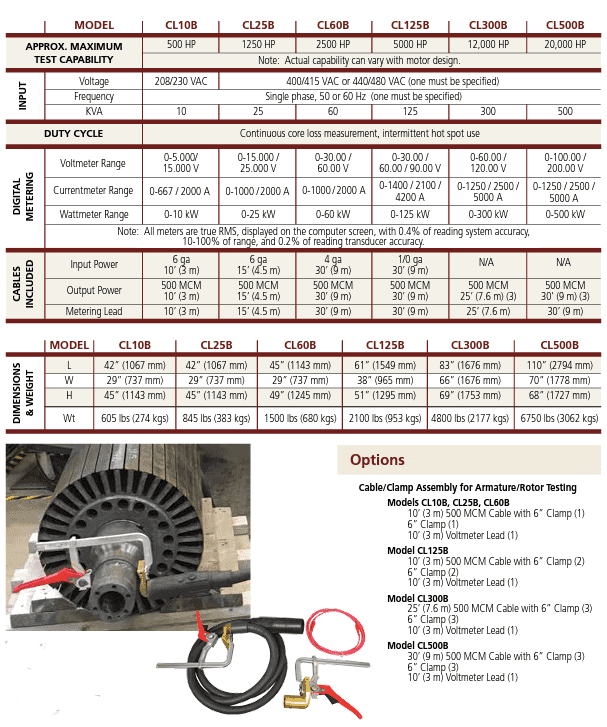

The Phenix Technologies Core Loss Test Set is a continuously variable low voltage, high current power supply for testing stators, rotors, and armature cores. These units have very low distortion, independent of load and output setting. This insures test results that are both accurate and repeatable. The basic test set includes complete instrumentation, output and voltmeter cables, computer and printer. The computer is used for complete control, metering, data storage and evaluation of test results. Operation of the test set is as easy as hooking up the test leads, typing in the parameters of the test and pushing a button. The test set takes over from there; automatically ramps up the voltage, records the results, does all the necessary calculations and ramps the voltage back down. The automated function eliminates operator error; several pre-programmed messages will alert the operator of test set up errors, saving time and increasing operator safety. A database can be built for specific motors tested. Past results can be easily accessed when re-testing a motor that has been tested in the past, making trend analysis quick and easy. The operating software interfaces with the test sets Programmable Logic Controller (PLC) that in turn guides the test set through its test functions. The PLC eliminates a large portion of circuitry required in manual test units. With less circuitry, the test set becomes much more reliable and easier to troubleshoot if a problem does occur. Precision control of the output setting is possible with 3-5 ranges per output tap. This translates into 3-5 times greater regulation of the output voltage setting. A meter calibration is done through the computer; saving time and insuring accurate readings. There is no need to remove panels off the test set to calibrate the metering. The duty cycle allows the operator to overexcite and heat the core sufficiently to locate hot spots.

- Main power circuit breaker

- Fused power control circuits

- Emergency Off pushbutton

- Multi-range digital meters

- External interlock provision

- Continuously variable output

- Thermal overload protection

- Output is controlled by a motorized voltage regulator with variable rate of rise

- Output cables for stator testing

- Internal, external, and transient overload protection

- Zero-start interlock

- Rugged steel cabinet

- Casters, lockable cover, and storage hook (CL10B, CL25B, CL60B, CL125B)

- Separate voltmeter leads for greater metering accuracy

- Operation/Maintenance manual

The function of a core loss test set is to determine whether a motor has damaged core iron. Damage could include shorts between laminations and damage caused by winding failure. A vital step in the rewinding of a motor is performing a core loss test before the windings are removed to detect any damage to the core. After the windings are removed, the core should be re-tested to verify that it was not damaged during removal of the old winding. Although it is possible for a motor to still run with core damage, the efficiency of the motor will be greatly reduced. The motor will consume more power to operate at normal levels and it will cause the motor to generate more heat. Heat will in turn reduce the reliability of the motor and its overall functional life. An increase of 10°C in the winding can reduce thermal insulation life by half. All of these consequences add up to more operating and maintenance cost and loss of production time.