Confident Asset Health Decisions Start with Real-Time, Quality Data

Good decision-making requires good data. The more real-time insights power and utility teams have into asset health condition, the better positioned they are to act quickly and effectively at the first sign of a health concern. Intervening early is the best way to avoid failure.

Many teams today rely on manual oil sampling. The process can be prone to errors and contamination, and slow to deliver actionable insight. By the time a team analyzes the results and understands there’s a problem, the issue has likely gotten even bigger and more impactful.

Speed, efficiency, and comprehensive information are linchpins for grid reliability. To ensure today’s utilities are fully equipped to deliver the highest levels of asset performance, Doble has released a new hydrogen detector designed for real-time information gathering and fast intervention against faults.

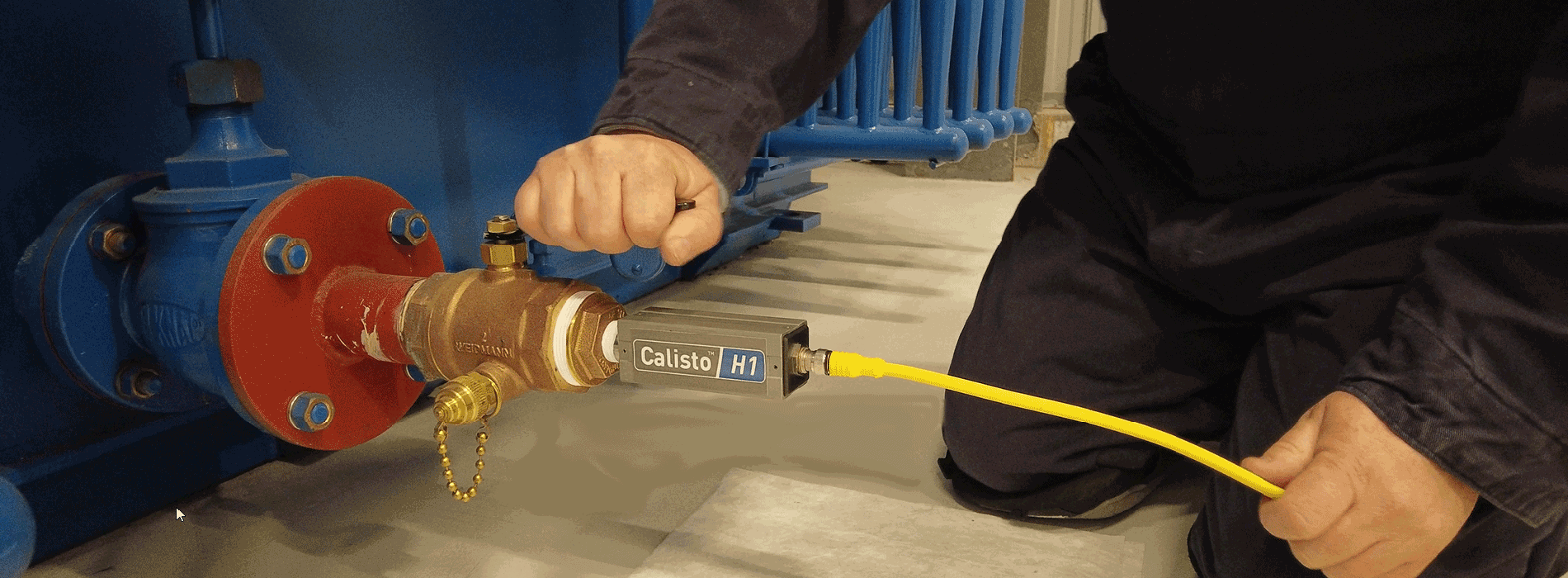

Calisto H1: Doble’s new hydrogen sensor for transformers

Calisto H1 is the industry’s premier solid-state hydrogen sensor technology. By taking real-time oil measurements, the device gives utilities more health information to work with – and faster.

The detector is installed directly on a transformer valve and continuously samples the oil within the asset, measuring hydrogen levels. Power and utility teams are automatically alerted of spikes and abnormalities that could indicate an electrical fault, eliminating the need for manual oil sampling.

Without having to send personnel into the field, or the sample to a lab for analysis, teams are better positioned to swiftly and safely catch and address asset health issues. Staff exposure to potentially volatile situations while collecting oil on-site is dramatically reduced. The real-time results and broad view of overall power system performance ultimately give teams more confidence in their decision making and asset health strategies.

The device gives teams the flexibility to monitor a greater number of assets, including smaller and lower risk transformers, cost effectively. Calisto H1 is built to take proactive measurements on its own, and feed into a larger asset performance program. The detector seamlessly integrates as an additional monitor within the Calisto™ Condition Monitoring platform.

Other key benefits of the hydrogen detector include:

- Seamlessly integrate H1 data, along with data from other Doble condition monitoring instruments into doblePRIME software for improved decision-making.

- Manage communication via Modbus for data exchange with other applications.

- Ensure functionality over a broad temperature range with IP68 ingress protection and high EMI/RFI ratings.

- Withstand even the harshest applications including small distribution, vault, wind farm, and railroad/traction transformers and offshore platforms.

Doble is committed to making asset performance management as easy and valuable as possible. Even with the real-time information, teams still need to know what the insights mean, how to act on the data and the significance of transformer condition changes. This is why our team of experts work hand in hand alongside power and utility companies to provide that vital context and offer advice on how to resolve their specific concerns and situations. We’re here to support you, every step of the way.

To learn more about Calisto H1 and its key features, please visit here.

Additional Information:

- Product brochure: Calisto H1

- News: Doble Brings Condition Monitoring to More Transformers with Calisto H1

- Further reading: