How the Calisto R9 is Transforming Dissolved Gas Analysis

Dissolved gas analysis (DGA) is essential for utility professionals worldwide to keep the power grid running safely and efficiently. No other tool provides better insight into transformer health.

Online DGA monitoring brings the added advantages of early fault detection and the ability to keep gassing units in service while further tests or interventions are planned. Recently, DGA condition monitoring has grown in importance. Utilities are working to extend the service life of aged units to meet increasing electricity demand in the face of unprecedented long lead-times for new transformers. Moreover, the shortage of asset management professionals has put a premium on condition monitoring solutions that reliably deliver actionable DGA data while requiring low maintenance time and cost.

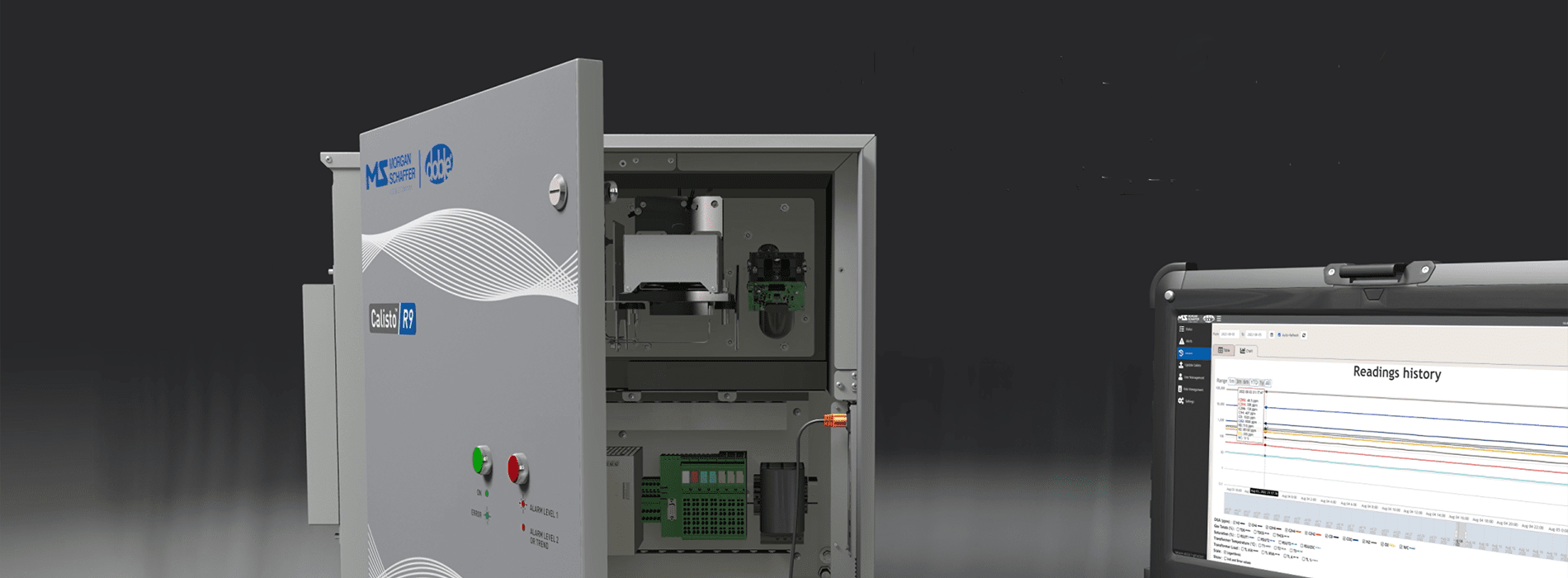

That’s why we are so are excited to introduce The Calisto® R9 Online DGA Monitor. The latest addition to the Calisto family provides asset managers with an opportunity to better manage transformer fleets, while saving time, money and resources. With no consumable gases to replace and innovative gas measurement technologies, the R9 is low-maintenance, accurate and built for years of service. Here are the ways the next generation Calisto R9 is creating a new way for DGA.

Accurate Gas Measurement and Analysis

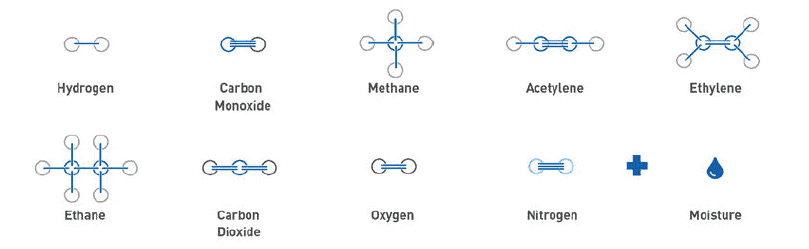

Online DGA monitoring provides a deep view into the operational health of a transformer. Real-time gas readings allow asset managers to promptly identify deteriorating conditions and respond accordingly. The Calisto R9 measures all key transformer fault gasses hourly, including hydrogen (H2), carbon monoxide (CO), methane (CH4), acetylene (C2H2), ethylene (C2H4), ethane (C2H6), and carbon dioxide (CO2). The monitor also reports moisture and the air components oxygen (O2) and nitrogen (N2). Current and historical readings can be viewed with the intuitive Calisto R-Series Web Interface that runs with any common web browser.

Measures All Key Fault Gases Plus Moisture

Proven membrane extraction prevents oil and oil vapors from contaminating the gas measurement system over its lifetime. PTFE capillary tubing forms a semipermeable membrane for true equilibrium gas extraction. The membrane is vacuum tolerant and ensures that transformer fluid or vapors cannot contaminate the gas measurement system even during transformer or monitor maintenance. For maximum DGA accuracy, the product is preconfigured with Ostwald solubility coefficients of common oil types.

The Calisto R9 is built and tested to meet rigorous international standards for EMI/EMC, safety, vibration, and extreme environmental conditions. Each firmware release is thoroughly tested to withstand the latest cybersecurity threats. The system also provides all the communication features needed for seamless integration into smart substations including protocols DNP3, Modbus, and IEC61850.

Early Fault Detection and Diagnosis Using our Advanced Infrared Method

To ensure the health of the power grid’s most important assets, power and utility teams need equipment that’s hassle free, yet highly accurate.

Doble’s U.S.-patented Differential Infrared Photoacoustic Spectroscopy (DIPAS) method and proprietary thermal conductivity for hydrogen enable the monitor to accurately measure even small concentrations of gases and provide dependable DGA measurements. The benefits to utility teams include early fault detection, accurate fault diagnosis, and actionable risk assessment. One discerning aspect of this method is that accurate readings are provided even if the fluid contains unexpected dissolved gases such as SF6 or heavy hydrocarbons common in aged transformers.

Automated Calibration with Water Vapor for Long-Term Accuracy

DGA monitors can drift over time, leading to inconsistencies with laboratory DGA results and, in extreme cases, false alarms or undetected transformer faults. Monitors that use gas chromatography (GC) maintain their accuracy over time using on-board calibration gas to periodically calibrate themselves. In a similar way, the Calisto R9 uses water vapor from a small reservoir to routinely calibrate the gas analyzer. This approach provides long-term accuracy of the gas readings without the cost and effort associated with changing compressed gas cylinders.

Calisto Experience Built-In

Morgan Schaffer has been designing, manufacturing and supporting DGA monitors for more than 20 years. In that time, we have continuously refined our designs and processes based on the experience of our clients around the world. The Calisto R9 benefits from many of our lessons learned. It uses the same ultra-reliable sludge-tolerant pump as earlier Calistos, eliminating the need for maintaining an oil filter. Our oil-flow monitoring system ensures that representative oil samples are being analyzed. Precision thermal controls create laboratory-like conditions in the gas extraction and measurement systems. Reliable and consistent gas extraction is achieved using semi-permeable tubing as in thousands of Calisto units deployed around the world. The intelligent bubble trap simplifies installation and protects the transformer from gas bubbles that could compromise the dielectric system. Taken all together, the Calisto R9 has the lineage to ensure dependable condition monitoring for any transformer fleet.

The Best of Both Worlds

To meet the evolving needs of utility professionals, the next generation Calisto R9 integrates ground-breaking new gas measurement technologies with field-proven design features. Like other IR-based DGA monitors, it is easy to install and operate. Like GC monitors, it automatically calibrates itself to provide accurate DGA readings over the long haul.

Our product support engineers have an outstanding reputation for client service. They are looking forward to helping our customers experience our new way for DGA.

For more information about Calisto R9, visit www.doble.com/calisto-R9. To request a demo, speak with your Doble representative.

Additional Information:

- Product: Calisto® R9

- Blog: