Calisto® Cable Condition Monitoring Solutions

New insights for your critical cables

Doble’s cable monitoring is pushing the boundaries of condition monitoring and is helping the electric power industry operate cable systems of any voltage in a more reliable, safe and secure manner. Using near real-time asset health and condition data, we help protect critical power cables and connected assets, safely ensuring uptime, and reducing traditional operating costs.

Built on the same core technology used for manufacturing and commissioning acceptance testing, our solution helps customers prevent major faults in transmission and distribution cables by identifying:

Reduce your cable’s total cost of ownership using real-time cable condition data

Reduce your cable’s total cost of ownership using real-time cable condition dataThe Doble Calisto® Cable Condition Monitoring Solution provides information on cable systems beyond insulation and accessories health. It allows for virtual asset inspections and predictive data-driven maintenance programs, both of which can greatly reduce the total cost of ownership (TCO) for HV cables. It’s a flexible platform that integrates multiple monitoring parameters, and is supported by Doble’s expert engineering team.

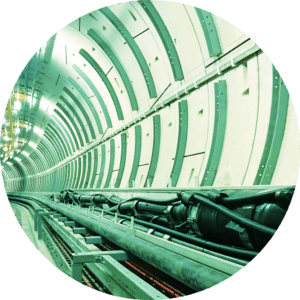

Comprehensive monitoring of underground HV cables can protect your critical investment with minimal additional cost. Typically deployed along with the cable during construction, the cable monitoring system is installed at both terminations and splices, monitoring the most common sources of cable failure. Integrating temperature, vibration, displacement, and streaming video into the same monitoring system provides a way to protect the asset, and reduce operational costs associated with that cable.

Online cable monitoring continuously monitors the PD activity in HV cable using Techimp state of the art technology and patented TF Map™ noise rejection. The system is configurable in order to reject noise and to acquire only partial discharge signal for the alarm evaluation. It is also possible to discriminate different type of phenomena, and assign to them different alarm algorithms with different thresholds. Data can be visualized as Phase Resolve Partial Discharge (PRPD) standard pattern (with multiple selection for comparison) as well as TF Map. Statistical parameters are also provided for each acquisition.

The cable monitoring solution, by continuously measuring and trending partial discharge activity, helps our customers to prevent major faults in HV cables. Main defects in HV cables are:

Different aging processes are at the same time present on the same cable circuit:

Permanently monitors the PD activity of HV cables. It is a modular system that includes:

The Doble Cable Monitoring solution has modular and flexible architecture that allows global monitoring system design according to our customer requirements.

The PD Hub is the core of the PD monitoring system and is available as a 3, 6, 9 and 12-channel device. Its UWB acquisition unit operates from 16kHz to 30MHz with a fast sampling rate of 100MS/s and captures the entire waveform of a large number of pulses. The TF Map allows to differentiate between different pulses with different shapes (TF Map) hence improving the signal to noise ratio and collect mainly pulses related to PD activity. The unit is powered and protected by a LV switchboard. The PD Hub is available in IP65 as well as IP68, where required. Usually the PD Hub is installed close to the cable terminations and cable joints

Several sensors are used to detect PD signals coming from inside the cable. The most often used type of sensor for cable PD monitoring is the HFCT. TECHIMP’s family of HFCT combine an excellent frequency response with robustness a long-lasting installation. At cable terminations, sensors are usually installed inside grounding boxes or directly on the ground connection cables at GIS or transformer termination. At cable joints, HFCT are integrated in the link-box either around the ground connection cables or around cross-bonding bars inside. TECHIMP offers a wide range of sensors:

PPS concept has been developed to allow permanent PD monitoring on HV cable joints when there is no LV power available at the manholes. PPS gets the required energy from the High Voltage power line under monitoring by means of one or more toroidal units clamped on the HV power cable(s). PPS is able to continuously supply up to 60W @ 24Vdc when the HV cable is energized and allows to have a synchronization signal for the whole cable monitoring system. PPS is made up of two main devices: the clamp toroidal transformer (180mm diameter max) and the electronic controlled supply unit. Depending on the power level required from the PD system, the PPS is able to provide up to 60W using up to three clamp transformers.

The central unit is a 19” rack cabinet containing the server and the processing software. The server is an industrial PC with redundant hard drives and power supplies, to ensure maximum reliability. The software is supplied as virtualized system (Virtual Machine), so it can be easily restored and moved to other machines. The central unit contains also an industrial monitor and a keyboard/mouse. It can be provided with an UPS and a WatchDog unit capable to notify system alarms.

The PD Acquisition Unit installed inside each PD Hub shall be powered by means 5 Vdc, 2 A max. The PD Hub shall be powered by a low voltage power feeder through the protection switchboard installed inside. All PD Hub and the central unit are connected together by means of a fiber optic network

This network is made as a loop, in order to prevent a failure in the communication in case of interruption of one segment of fiber. The fiber can be either single-mode or multi-mode, terminated with ST connectors.

Most cables are distributed with splices (the most common failure point for HV cables). Doble monitors the splices and the terminations. This is typically where we will permanently install our distributed cable monitoring system with PD monitoring.

The graphical interface of the TECHIMP PD Monitoring System (TiSCADA) reports the status of the monitored electrical assets in a single synoptic screen (named “synoptic view”). This screen allows to spot any part of the insulation system affected by partial discharges. In addition it is possible to analyze acquired data, to plot data trending and to perform advanced queries to the Database (e.g. comparing data among equipment of the same plant, among the phases of the same EUT, the PD data can be correlated with the trend of other monitored quantities such as temperature, load, etc…). Thanks to the Web Server the graphical interface of the system can be accessed locally or by any other user connected (by means of LAN or modem) to the Central Control unit, with proper login credentials. Allowing maintenance personnel and asset management to access the PDM data with no need of dedicated software.

The same technology used for MV cable acceptance testing, and for non-destructive online testing, can now be permanently installed providing near-real time monitoring of your critical distribution assets. Due to the density and design of many facilities and distribution networks, Doble’s cable monitoring solution for MV cables has many form factors to accommodate the various environmental conditions and densities of distribution. Deployed with new assets or as a retrofit of existing cables, our solution for MV has the added benefit of identifying partial discharge (PD) in the terminal assets connected to the MV cable. The PD acquisition units used for the MV cable monitoring system are also used to identify PD in switchgear, circuit breakers and transformers.

FALCON represents a cost-effective solution for the continuous monitoring of PD in MV assets such as, MV Switchgears, MV Cables, MV Transformers and MV Motors. FALCON can identify the deterioration of insulation and the possible degradation of the health of the electrical system, before a failure. The FALCON unit acquires and processes high frequency PD signals, locally detected by the sensors to which it is connected, whether inductive (HFCT) or capacitive (TEV).

FALCON represents a cost-effective solution for the continuous monitoring of PD in MV assets such as, MV Switchgears, MV Cables, MV Transformers and MV Motors. FALCON can identify the deterioration of insulation and the possible degradation of the health of the electrical system, before a failure. The FALCON unit acquires and processes high frequency PD signals, locally detected by the sensors to which it is connected, whether inductive (HFCT) or capacitive (TEV).

A FALCON KIT comes with a sensor, a synchronization kit and the embedded web application. FALCON is a plug & play device that can be installed with only a few simple operations. It configures itself automatically and once powered, it is immediately operational. Another important advantage of FALCON is its capability to be easily integrated into an existing monitoring system. FALCON supports the IEC 61850 and OPC UA protocols.The FALCON Unit is equipped with two magnets which allow the unit to be installed directly on the panel of the switchgear or with a DIN rail, for a different type of installation.

FALCON is equipped with an automatic full scale and trigger level adjustment system, which always guarantees the best accuracy.

There are different ways to visualize incoming alarms:

Based on the defect evolution, the FALCON offers an algorithm able to determine if an asset has critical levels of PD. In case the identified PD represents a danger, FALCON sends an alarm to the operator to inform that a critical issue is found. The alarms are given with 5 levels of severity:

All the information acquired is stored in FALCON memory and it is available via web application, PC, or smartphone.

When an evolving defect occurs, the web application immediately reports the condition of the asset and the criticality level of the defect. The interface is easy to read and doesn’t require any specific skills. It is therefore not necessary to be a PD expert to get immediate benefits out of the FALCON system.

The need to monitor many assets brings with it the need to manage a multitude of data. In the case of integrating the FALCON monitoring system with an existing infrastructure, the communication can take place via various protocols, such as IEC 61850, or the OPC UA, which allows the concentration of information from multiple units in one window.

Knowing your asset’s condition in near real-time can allow you to catch issues when they are small and before they escalate to catastrophic failures or unplanned outages.

Most cables are distributed with splices — the most common failure point for HV cables. Have Doble monitor your cables splices and terminations using a permanently installed distributed cable monitoring system utilizing our proven partial discharge detection methods and instruments.