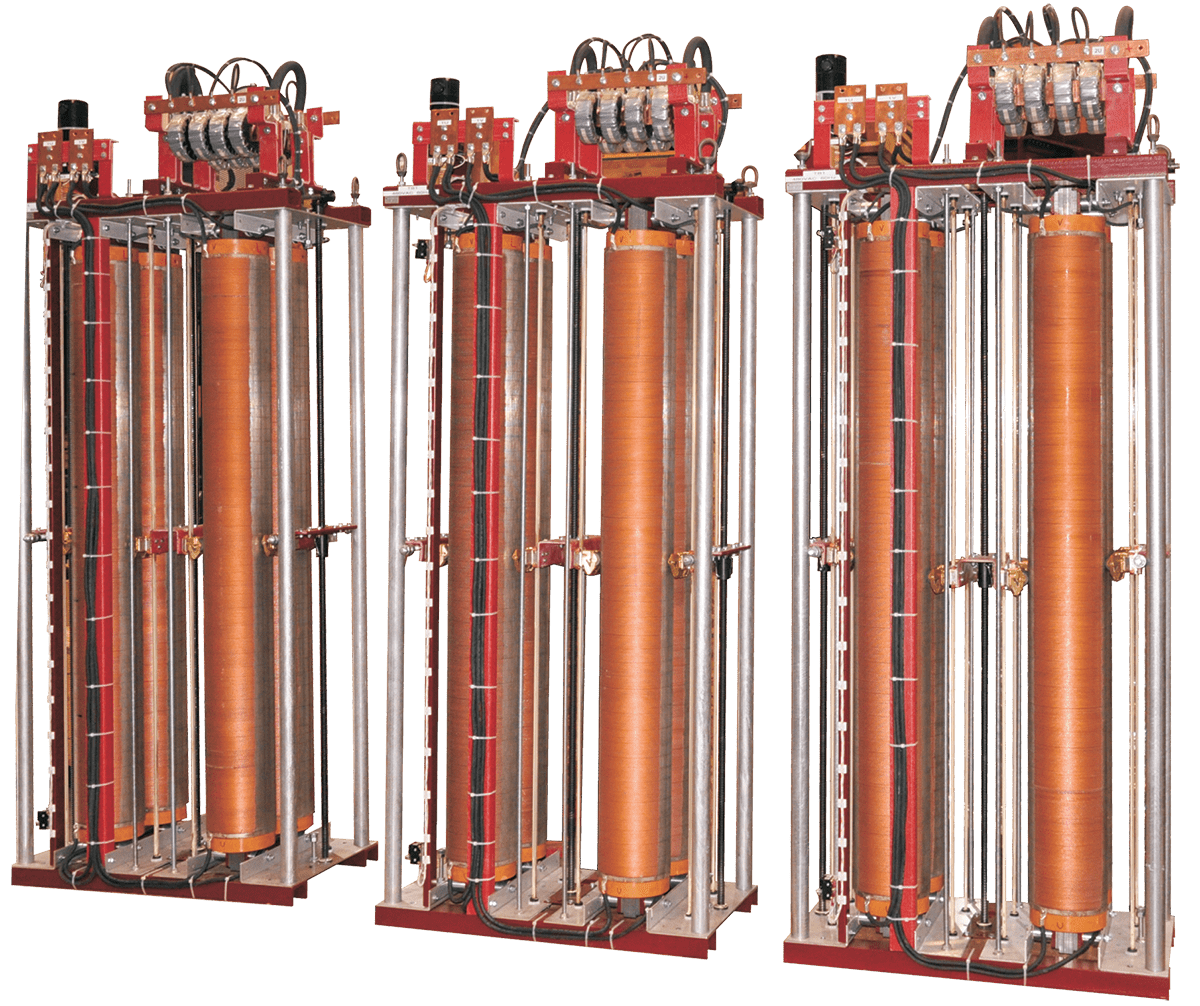

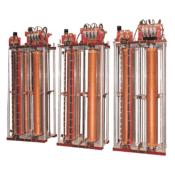

The CTVT is constructed of an outer copper coil, as well as a series of internal compensation coils, both encompassing a laminated steel core. The coils are encapsulated using a process known as vacuum pressure impregnation (VPI) to strengthen the column and provide uniform heat transfer. A contact face of the windings is exposed to reveal the individual turns. The face is then nickel-plated to provide a wear-resistant and corrosion-free path for current collection. A combination of aluminum and steel structures support the columns providing a heavy duty and structurally dependable unit.

Voltage Transformers/Regulators & Power Supplies

Phenix Technologies manufactures an extensive line of voltage regulators to accommodate the enormous variety of electrical equipment in use today. They provide an adjustable output voltage whenever a continuous regulation of AC voltage with load is necessary.

- Single and three phase configurations

- Nickel-plated commutator path

- Rolling carbon current collectors

- Unique plus/minus design available

- Motorized ball-screw drive

- Fixed or variable rate or rise

- Heavy duty construction

- Continuous duty to 40 degrees C ambient

- Upper and lower limit micro switches

- Modular design for extensive kVA capacity

- Low turn-to-turn voltage difference (.7 volts max)

- Quasi-stepless regulation from 0-100%

- Compensation winding on all columns

- Step-up output available for 0-115% rated input voltage

- Delta and wye auto-winding standard

- Operating frequency range from 50-60 Hz

- Minimal output distortion

The most important feature of the PHENIX CTVT is the low turn-toturn voltage difference across the transformer windings, (designed to never exceed .7 volts per turn). In order for a variable transformer to yield continuous, uninterrupted output voltage, the current collector must touch the next turn before leaving the previous one. The potential difference across the collector results in current flow, which results in heat dissipation. CTVTs use 35mm diameter carbon rollers as the collector device. In addition to eliminating mechanical problems associated with sliding contacts, the rollers endure greater cycles due to decreased friction. The carbon offers excellent electrical conductivity as well as exceptional thermal withstand capabilities. When the rollers bridge two turns, a combination of the low potential difference and the resistance characteristics of the contact devices limit current flow throughout the roller. These properties make the PHENIX CTVT ideal for applications in which the rollers are stationary or do not experience frequent movement.

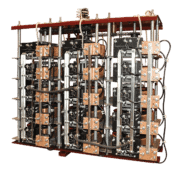

The PHENIX CTVT uses two types of roller holders. Termed three-holder and four-holder; the first holds 3 carbon rollers and the latter 4. With each roller capable of carrying 25 Amps, the face of each column is able to provide up to 100 Amps of current. However, the unique double current collector design

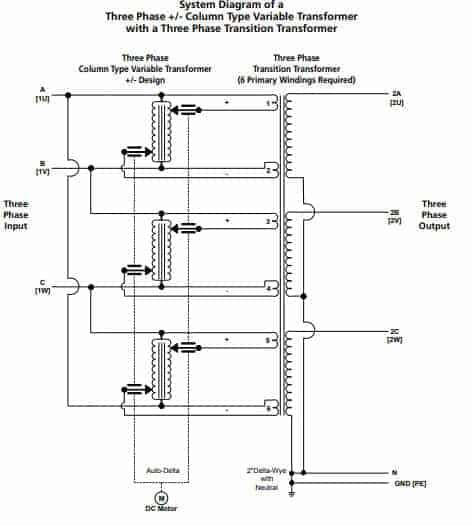

termed “plus/minus” allows for higher KVA throughout than conventional autotransformer designs. A roller assembly is installed on both sides, but at opposite ends of the column providing two output circuits for each column, thus doubling the KVA capacity. The plus/minus design is ideal for stabilizer applications in which a buck-boost transformer requires regulation capable of shifting voltage polarity.

Each CTVT contains a compensation winding located beneath the actual commutating winding. This ensures a uniform current distribution across the length of the column, providing a much improved regulator impedance characteristic. The result is minimum voltage drop and increased efficiency.

Phenix designs the motion of the current collectors by using a motor drive attached to a ball-screw and miter gear assembly. Fixed or variable rate of rise is achieved through the use of an AC or DC gear motor. Common regulation is 0-100% in 1 minute for AC units, 30 seconds for DC units, with custom speeds available. The use of high quality miter gears and pillow-block ball bearings linked to a ball-screw drive eliminates problems associated with conventional chain drives. The result is a mechanically reliable unit, with a long life and minimal maintenance.