Perform electrical testing on worker’s rubber goods personal protective equipment. The item is electrically tested beyond its maximum field use to make sure that it can withstand the electrical stress it will be subjected to while in use.

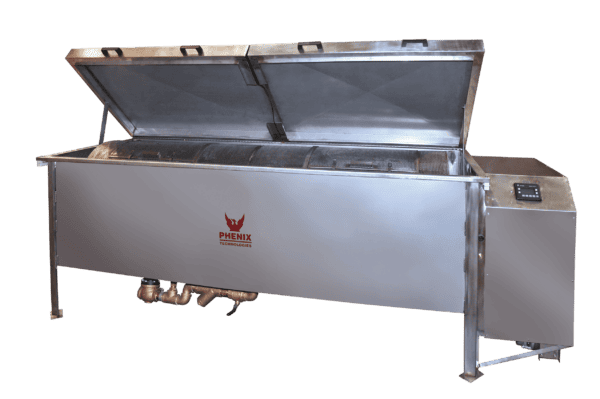

Rubber Good Washer

- Automated wash cycle

- Rotating drum design

- Constructed entirely of 316 stainless steel

- Two drum sizes are available:

- 22”(559mm) diameter & 84”(2134mm) long

- 30”(762mm) diameter & 96”(2438mm) long.

- Handles large quantity loads of all types of different

rubber goods

Rubber Good Dryer

- Can be used to dry rubber products such as gloves, hoses, hoods, blankets, boots and overshoes

- Static type design helps prevent pinches and tears that occur in a tumble type dryer

- Heat cycles on and off to provide even heat

- Built-in temperature controller

Phenix Technologies’ test systems are designed for fast, accurate, and safe testing. Our user-friendly HMI combined with Programmable Logic Controls performs your specified test from pre programmed test parameters at the touch of a button. Many automated features increase efficiency and safety. Phenix Technologies offers solutions to furnish any type or size rubber goods testing lab.

- Test systems can be configured in many ways for optimal efficiency

- Multiple test stations can be powered from one power supply

- Each test station uses an optically isolated control network for reliability and safety

- WINRGTS software allows data storage on a separate PC

- Complies with all the latest IEC and ASTM standards

All cabinets are constructed of 12-gauge cold-rolled steel, primed and painted with two urethane topcoats for rust prevention. For the safety of the operator, all panel doors and access doors are electrically interlocked so that any attempted entry into the test set while it is in operation will cause the power to shut down. Superior ozone removal system features 1100 CFM exhaust fans with direct free air intake and circulating system. The systems size will depend on the number of test positions required.

The Power Supply module houses the high voltage transformer, regulator, and control panel.

- Various combinations of Power Supply modules are possible.

- A single power supply module can power several different test units with the use of an optional HV transfer switch.

- Two power supply modules can be joined to double simultaneous testing capabilities for large volume testing requirements.

- The system can be configured with AC or DC power supplies or both AC and DC to meet applicable test standards.

- Computer interface

Each system’s Control Panel features an HMI interfaced with Programmable Logic Controls. A number of programming options make testing more efficient and reduces the chance of operator error. Some of the possible functions performed at the touch of a button include:

- Instantly change the parameters of the test to meet the specified standard

- Switch testing from one product to another; such as, gloves to sleeves or blankets

- Change the testing requirements for different classes of rubber

The HMI displays precise, easy-to-read test results and will immediately inform the operator of any failure at a specific test station. All test results can be downloaded to a computer and test reports can be generated with WINRGTS software.

Our Modular Design options are beneficial to the customer that tests a variety of different rubber products. The test chambers are separate from the power supply and control panel. Different configurations allow customers more flexibility inside their facility. Systems can be built in L-shapes or in a straight line.

Overview

- Gently tumbles rubber gear with low RPM (25) to avoid any wear or damage to rubber

- Gear-driven chain drive for very quiet and long-term operation

- Solidly constructed of 316-grade stainless steel

- 2 lightweight latching access doors

- Manual or Automated controls

Standard Design Features

- Circuit breaker for main power

- Wash chamber has safety interlock

- Cartridge-type inline water filter

- Recirculation pump for hot water supply

- Auto-fill feature

- Wash / rinse timer with audible alarm

- Drum jog feature

- Solid brass drain valve

- Water tight pushbuttons

INPUT: 120 or 240 VAC, 1 Phase, 50/60 Hz

DUTY CYCLE: Continuous

Environmental Conditions

- 10-40°C, indoor/outdoor in fair weather

- Humidity <95% non-condensing

- Altitude <3300 ft (1000 meters)

Note:

- Level, concrete floor with drain is

recommended - Customer-supplied hot water line with a normal household psi rating (approx. 40 psi)

Designed to dry rubber gear either after washing or electrical

testing

- Items are positioned on open racks and circulating air

dries items within minutes - Static-type design helps prevent pinches and tears that

occur in a tumble type dryer - Totally self-contained with exhaust fan to remove

humidity and heat - See-thru doors allow for visual inspection

- Built for many years of trouble-free service

Capacity

- 50 gloves or 50 sleeves or 70 overshoes or 12 blankets

or 35 hoses or 25 hoods

Enclosure and Design Features

- 12-gauge primed and painted cold-rolled steel cabinet

- 12-gauge stainless steel floor

- ½” LEXAN hinged, see-thru doors

- 10” exhaust fan rated 665 CFM for moisture removal

- 5 corrosion resistant racks angled to allow items to

drain during the drying process - 50 (10 per rack), 100 CFM fans for hot air circulation

located in rear of cabinet - 35,000 BTU electric heater mounted on top of cabinet

for accessibility

Controls

- Controls include circuit breaker, start and stop buttons,

and indicator lights for fans and heater - Digital thermostat with high and low set-points

- Digital timer for heat/fan cycle times

- Programmable heater control

INPUT: 208/240 VAC, 60 Hz, 1 Phase

OUTPUT: 10 KW, 35,000 BTU

81” (2050mm) L x 52” (1310mm) W x 88” (2245mm) H’;

1,000 lbs. (455 kgs) (approx.)