EMI Diagnostics: Emergency Diesel Generators

Electro Magnetic Interference (EMI) is produced by electrical and mechanical defects in many types of equipment. The precise measurement of EMI will provide a condition assessment for an emergency generator and associated power system. Data is collected during a normally scheduled test run with a split core radio frequency transformer (RFCT) placed around the power conduit to the generator as shown below. The data collection is completely passive, no signal is injected into the system.

Placement of the RFCT to collect EMI data.

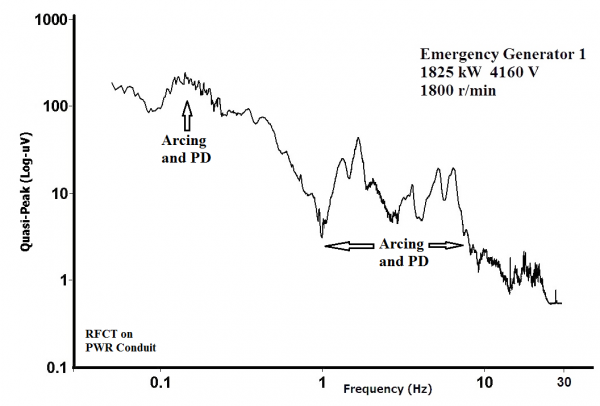

The curve produced is an EMI Signature.

The EMI Signature captures all EMI over a wide spectrum of frequencies. The patterns seen are identified by a test engineer and the type of problem and a location can be determined. At this location one generator had failed the operators wanted to know the condition of remaining generators. Generator #1 has severe arcing indicating a broken stator winding conductor and partial discharges (PD) indicating compromised insulation. A 4 kV stator should have no arcing or PD. Yes the #1 generator was deteriorated and needed to be rewound before it failed. Advantages of using the EMI Test on emergency diesel generators are:

1. Test is made while the unit is energized during periodic test run

2. Problems are detected in early so timely corrective measures can be taken

3. The generator, exciter, voltage regulator, power cables and breaker are evaluated

4. Verification of generator system conditions and reliability are enhanced