F8000 Command Module: The Gateway to Next Gen Protection Testing

Modern protective relays are computer devices capable of immense functionality. In the decades since microprocessor technology first made impacts on relay designs and applications in protection schemes, tangible benefits of automation, communication and control have raised the profile of relays in networks across utility and industrial substations.

The importance of relay testing cannot be overstated given the consequences of protection system failures in today’s power delivery environment. The role relays play in protecting power transformers, generators, motors and other critical electrical components hasn’t changed, but protective functions are now just a portion of what must be verified during tests. Modern relays can have thousands of setpoints and can be configured for increasingly sophisticated applications. Personnel must adapt test systems and practices to accommodate analog, digital, and hybrid analog-digital protection schemes at their companies in an era when there has never been more scrutiny of their work.

The expenses and complexities of modernizing protection systems with new, advanced relays are exacerbated by test equipment limitations. Proving relay functions requires multiple intricate analog and digital simulations. Test systems must comply with standards and protocols for communication and timing used in substation networks. When limited by test gear, companies might either forego using the added functions of modern relays or move forward by leveraging new relay capabilities with different test gear for specific, one-off purposes.

Having different test instruments for different protection applications causes inconsistencies that can eventually undermine test and maintenance program effectiveness. Companies can be pressed into a false choice between standardization or flexibility and become stuck in the status quo where reaching their asset management objectives remains elusive in the face of compounding equipment and software variables.

Doble F8000-series Power System Simulators let companies move forward with evolving protection technologies without disrupting existing operations. By providing feature sets that are modular, Doble F8000-series instruments can be offered in numerous configurations. Companies can select F8 instruments that have the configurations they need for their unique testing requirements. As a platform, the F8000 line of four- and seven-module instruments provide a consistent user experience across all configurations that are offered.

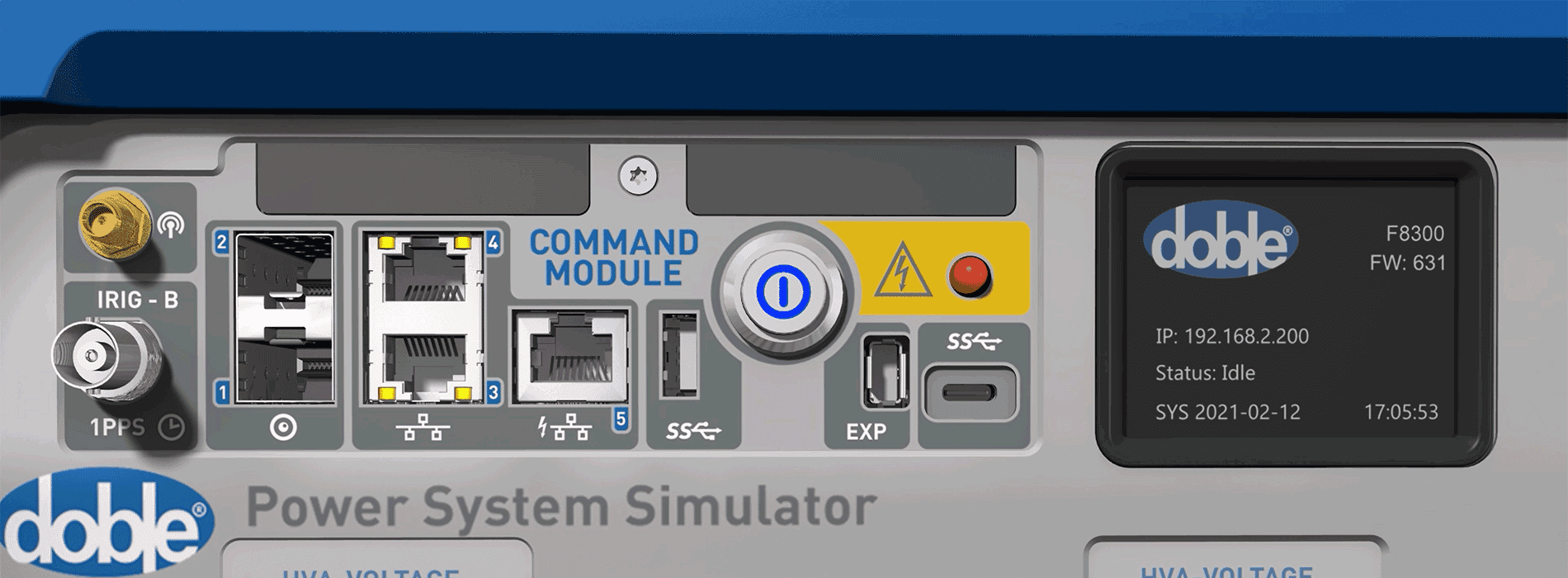

The key component of each F8000-series Power System Simulator is the embedded Command Module which opens a world of possibilities for secondary injection testing across the numerous instrument configurations of current, voltage and logic I/O modules on the F8000 platform. By design, the Command Module enables comprehensive analog, digital, and hybrid analog-digital test cases driven by Doble Protection Suite™ and Doble RTS™ software.

Compliant with substation networks

Relays must be precisely time-aligned to other devices in substation networks. Testing relays in system simulations requires test equipment that supports the timing standards used in substation network communications and provides exact synchronization with signals in play between devices.

The Command Module hosts advanced electronic components that provide the needed connectivity and performance for relay system test operations from F8000 Power System Simulators.

The GPS port works with satellite receiver antennas, like the Doble F8895, to synchronize F8000 instruments to substation network time-of-day references. A port is provided for synchronizing F8000 operations to the timing of communication signals according to the IRIG-B protocol which is commonly used in substation control systems. Synchronization at pulse-per-second (PPS) timing is supported by default and there is the F8053 firmware for complying with 100 nanosecond Precision Time Protocol (PTP) time resolution which is used by network Grandmaster clocks. The two copper and fiber selectable SFP ports and the three RJ-45 ports offer Ethernet connectivity for interfacing directly with conventional microprocessor-based relays, digital Intelligent Electronic Devices (IEDs), network switches or other computerized protection and control devices in substation networks.

Supports testing digitally

Getting online with the IEC 61850 standard can be easier said than done. Applying IEC 61850 in new substations is far less complicated than upgrading substations that are already in service. Utility and industrial companies can struggle when confronting new test requirements presented by digital protection systems when their existing testing program is designed around conventional relay testing.

The Command Module allows companies to have a single test instrument that offers the flexibility to test digitally with virtual simulations on IEDs (using Protection Suite), or to test with analog simulations on conventional relays (using Protection Suite or RTS). The flexibility to support both virtual and conventional simulations in the same test sequence – hybrid testing – is also supported.

The powerful virtual test and analytical operations in Protection Suite work through the Command Module which can isolate control, sampled values (via F8870 module), GOOSE (via F8860 module) and PTP networks, and separate or overlay discrete signals according to parameters configured in the software.

The feature sets provided with F8000 test instruments through the Command Module give companies the best of both worlds. They can maintain existing relays and implement the latest digital protection technologies from one test set that provides all the features and capabilities that are necessary either way.

Standardization that doesn’t limit you

F8000-series Power System Simulators eliminate the need to have add-on test devices to accommodate different types of relay tests thanks to the network-compliant components built into the Command Module. Utility and industrial companies can equip their relay test personnel with F8000 instruments of any configuration and keep a consistent user experience across teams who may specialize in different types of protection testing.

The modular approach Doble has taken with the platform of F8000-series instruments offers flexibility upfront with configurations that are suitable for different purposes, and in day-to-day test situations whether analog and/or digital simulations are necessary. For personnel who test relays, having a single piece of test equipment with the volt-amps, required connectivity, and facilities for virtual testing can be a huge advantage day-in-and-day-out.

Modern protection testing shouldn’t be bound by test equipment limits. See the difference F8000-series Power System Simulators can make in your protection testing program.

Additional Information:

- Video: Doble F8000 – Command Module

- News: Doble Engineering Company Launches F8000 Power System Simulators

- Further reading: