Purchasing a New DGA Monitor? Read the Fine Print

Supporting Decisions

Dissolved Gas Analysis (DGA) is a great way to detect and diagnose transformer problems in their early stages by tracking increasing dissolved gas levels as conditions deteriorate. Data to support decisions must be both accurate and precise so that appropriate decisions are made in a timely manner. It is vital to review the specifications of available monitors as the details may not give the accuracy and precision needed in the field application.

The Need for Measurement Accuracy and Precision

Measurement accuracy tells us how close we are to the ‘right answer’ as might be expected from a laboratory test; precision tells us how repeatable we can make the measurement. We need to distinguish between the accuracy/precision of ‘typical results’ during calibration, compared to what can be achieved in the field: it is the field results which will support a decision.

Practical Case

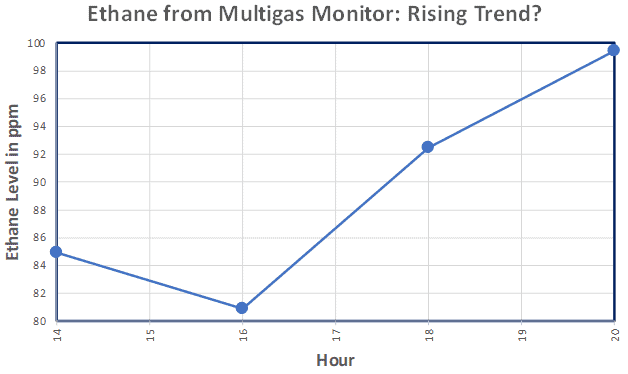

In the chart we see ethane data recorded every two hours using a Multigas DGA device – one with a 5% accuracy ‘during calibration’. The rising trend in the data, equivalent to a rate of change of over 100 ppm/day, is enough to cause concern about the viability of the transformer.

But is the trend real, or a consequence of the monitor? Do we need to remove the transformer from service, take a sample to check the data, in order to avoid putting the transformer and possibly personnel at risk? In fact, the data in the chart above reflects poor monitor precision and the variation seen is random error in the field measurement far exceeding the error during calibration or expected from ‘typical results’. Bad data can make it hard to make good decisions.

Check the Spec: Causes of Variation

When considering accuracy of a DGA monitor, it’s important to make the distinction between measurement of the gases from a gas bottle, usually during sensor calibration, and the measurement of gases in oil. The latter includes the circulation of oil, the conditioning of oil for gas extraction, the gas extraction itself and circulation of gases to a sensor.

Some monitors include the warning that oil or other chemicals may influence results. Oil degrades with aging and forms by-products, some of which are the gases of interest, but others are gases that can interfere with the accuracy and precision for some measurement technologies. Examples include low molecular weight acids, C3 and C4 hydrocarbons and others. Measurement instruments using infrared technologies may be more susceptible to these interferences leading to inconsistent results.

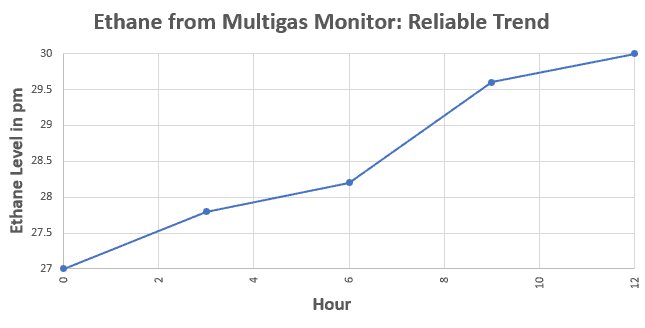

Below is an example of good accuracy and precision. Note that the data in the chart is repeatable and the variation is very small. The trend is reliable and supports a clear conclusion: ethane levels are rising, currently at about 6 ppm per day.

Conclusion

Online DGA monitors capable of an accuracy of 5% in the field, even with aged oil interferences, are available. Sadly, many electric power companies purchase online DGA monitors expecting 5% or 10% accuracy, only to find a variation of 50% or worse in practice. Buyers should insist on accuracy and precision for the entire integrated gas-in-oil monitor, not just the sensor’s ability to detect the gases of interest during calibration without commonly present interferences. Make sure you read and understand the fine print to make informed decisions when evaluating DGA monitors: true accuracy and precision for your intended application in the field.

ADDITIONAL INFORMATION

Product Information: Calisto™ T1 All-in-One Condition Monitoring System

Further Reading:

- Blog: Are You Prepared for What Your Technology is Telling You?

- Blog: Is SF6 Dissolved in Your Transformer Oil?